How to Choose the Right Steel Grade for Industrial Manufacturing — A Practical Selection Guide

Choosing the right steel grade for an industrial project means aligning alloy chemistry, mechanical behaviour and fabrication limits with the part’s performance requirements. This guide breaks down what grade selection actually involves, why the right choice matters for safety, service life and cost, and how engineers and procurement teams can make structured decisions around strength, corrosion resistance, manufacturability and whole-life value. You’ll get a clear overview of major classification systems (ASTM/SAE, EN, JIS), the principal steel families used in industrial components, and a straightforward framework to match common parts — shafts, gears, structural members and marine fittings — to suitable grades. We also include quick-reference tables, a procurement checklist, practical grade examples for heavy engineering and construction, and a note on how a bright-bar specialist like Dhand Steels helps you select and supply the right material for your build.

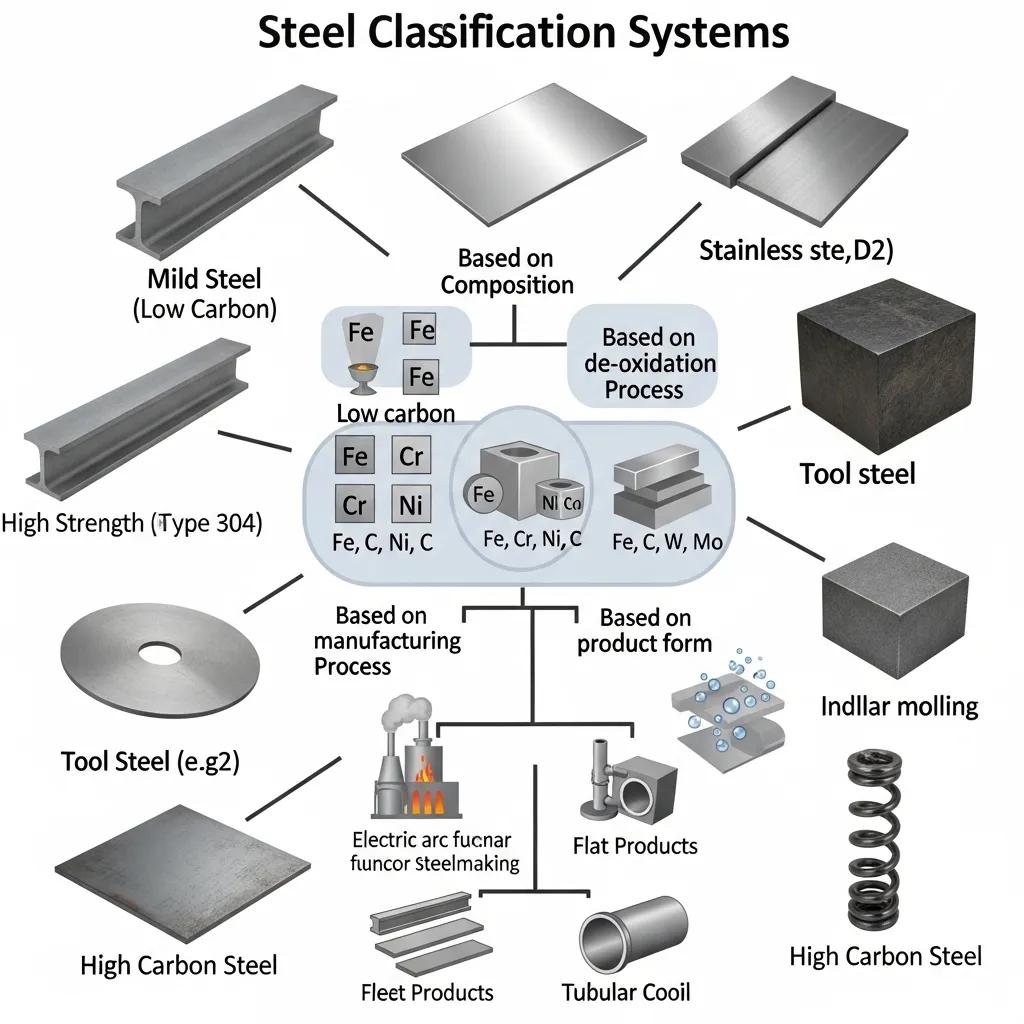

What Are Steel Grades and How Are They Classified?

Steel grades are standardized labels that tie chemical composition, processing history and expected mechanical properties to a formal specification. They exist so designers can specify materials predictably and suppliers can deliver consistent, verifiable performance. Different classification systems emphasise either chemistry or performance — some use composition codes, others define property bands — so knowing which system your drawing or spec refers to helps you convert a technical requirement into a procurable grade. This section introduces the main standards and explains how grade numbers or codes map to elemental ranges or property classes, giving you the vocabulary to write clear specifications and check supplier certificates.

This quick reference links commonly used grade labels to their classification systems and gives a short note on typical applications. Use it to cross-reference SAE/ASTM, EN and other labels without guessing at composition or intent.

| Grade Label | Classification System | Note |

|---|---|---|

| SAE 1018 | SAE / ASTM (carbon grade) | Low‑carbon, good formability — common for turned parts |

| EN8 / EN8D | EN (European) | Medium‑carbon engineering steel — often used for shafts and pins |

| SAE 4140 | SAE / ASTM (alloy steel) | Cr–Mo alloy with excellent strength after heat treatment |

Grade labels are shorthand for alloy chemistry and expected behaviour; using the correct mapping reduces specification mistakes and makes cross‑referencing between international suppliers reliable. Knowing which system a drawing references avoids costly substitutions and supports confident verification of certificates of compliance.

Which Classification Systems Define Steel Grades?

Classification systems group steels by chemistry, processing route and performance criteria to create repeatable procurement categories. SAE/ASTM codes are common in North America and often signal composition (for example SAE 4140 identifies a chromium–molybdenum alloy suited to heat treatment). EN numbers describe European engineering steels used widely for machining and forgings. JIS and other national designations remain important in regional supply chains. Some specifications use performance bands (yield/tensile) instead of exact chemistry; understanding whether a spec is composition‑driven or property‑driven tells you if a precise grade match is required or if a performance‑equivalent substitute is acceptable. That clarity speeds buying decisions and lowers the risk of parts arriving with mismatched toughness, hardness or corrosion resistance.

What Are the Main Types of Steel Used in Industrial Manufacturing?

Industrial work typically draws from four broad steel families: carbon steels, alloy steels, stainless steels and tool steels. Each family offers a different balance of strength, ductility, corrosion resistance and response to heat treatment. Carbon steels (SAE 1010–1018, for example) are cost‑effective for formed and machined parts where corrosion resistance is not critical. Alloy steels (SAE 4140, EN24, EN19) add elements such as Cr, Mo and Ni to deliver higher strength and toughness after heat treatment — ideal for shafts, gears and axles. Stainless grades provide corrosion resistance for marine or chemical exposures, and tool steels prioritise hardness and wear resistance for dies and cutting tools. Choose between these classes by matching the service environment, mechanical needs and fabrication route.

What Key Factors Should Influence Your Steel Grade Selection?

Pick a grade by weighing five core factors: mechanical properties, chemical/alloying needs, environmental exposure, fabrication constraints and cost/availability. Each factor affects part performance, manufacturability and lifecycle cost. Prioritising these depends on application risk — safety‑critical rotating parts require different trade‑offs than non‑critical structural members — and on whether the specification expects a specific grade or a performance equivalent. Below is a concise checklist to help teams turn functional requirements into specifications suppliers can meet.

Core selection factors to discuss in design reviews:

- Mechanical properties: Define required tensile and yield strength, hardness and toughness.

- Chemical composition: Identify alloying elements needed for strength, hardenability or corrosion resistance.

- Environmental exposure: Specify corrosion, temperature and abrasion conditions the part will face.

- Fabrication needs: Confirm weldability, machinability and formability for your manufacturing steps.

- Cost & availability: Balance material cost with lead times and lifecycle maintenance expense.

These factors interact — for example, raising strength via alloying or heat treatment can reduce weldability — so document trade‑offs early. The table below breaks down key properties and shows how each one steers grade selection, helping engineers shortlist candidate steels.

| Property | Why It Matters | Selection Impact |

|---|---|---|

| Tensile / Yield Strength | Sets load capacity and safety margins | Choose higher‑alloy or heat‑treatable grades for demanding loads |

| Hardness / Wear Resistance | Controls abrasion life and service durability | Use tool steels or hardened alloy steels for wear‑critical parts |

| Toughness / Fracture Resistance | Reduces risk of brittle failure under shock | Specify grades with proven impact properties or apply tempering |

| Corrosion Resistance | Prevents degradation in aggressive environments | Choose stainless grades or plan protective coatings as required |

| Machinability / Weldability | Drives manufacturing cost and feasibility | Favor free‑machining variants or set preheat/filler requirements for difficult alloys |

This compact, property‑focused tool helps procurement and design teams convert performance needs into a short list of candidate grades and fabrication strategies.

How Do Mechanical Properties Affect Steel Performance?

Tensile strength, yield strength, hardness, toughness and ductility describe how a component behaves under load and during manufacture. These properties are measured with standard tests (tensile tests, Charpy impact, Rockwell/Brinell hardness) and directly influence design safety factors and dimensioning. Hardness ties to wear life and machining response; toughness indicates resistance to crack propagation under impact or cyclic loading. For rotating or fatigue‑sensitive parts, fatigue strength and toughness are decisive and typically drive selection toward heat‑treatable alloy steels such as SAE 4140 or EN24, which can be processed to deliver both strength and toughness. Specify target test values and acceptable heat‑treatment conditions rather than relying on grade names alone to ensure in‑service performance.

Why Are Chemical Composition and Environmental Resistance Important?

Alloying elements — carbon, chromium, nickel, molybdenum, manganese — control hardenability, strength, corrosion resistance and high‑temperature behaviour. Small composition shifts can change a grade’s suitability. For example, chromium improves abrasion and corrosion resistance; molybdenum raises hardenability and high‑temperature strength; nickel helps toughness at low temperatures. Service environments such as marine atmospheres, chemical exposure or elevated temperatures require either corrosion‑resistant alloys (stainless) or robust surface protection. Specify environmental criteria (chloride exposure, operating temperature range) in your material specification so grade selection aligns with real world conditions and maintenance expectations.

How Do Fabrication Requirements and Cost Impact Steel Grade Choice?

Fabrication constraints — weldability, machinability and formability — often limit feasible grade choices because some high‑strength alloys need special machining or joining procedures. Material cost and supply chain availability determine whether you can specify an ideal grade or should approve a performance‑equivalent substitute with lower cost or shorter lead time. This section outlines practical trade‑offs and procurement tactics to keep projects on schedule without sacrificing performance.

Capture fabrication considerations during design-to-manufacture reviews so teams can make informed trade-offs between material properties and manufacturability. Use this procurement checklist to decide when to insist on a specific grade and when to accept a substitute.

- Verify fabrication compatibility: Confirm the selected grade can be welded, machined or formed with your shop’s capabilities.

- Check lead time and stock: Validate availability to avoid schedule delays.

- Assess lifecycle cost: Compare upfront material cost with expected maintenance and replacement expenses.

- Evaluate substitution impact: Approve substitutes only after tests or calculations show equivalent performance.

For safety‑critical or high‑downtime components, a slightly higher‑spec material often reduces lifecycle risk; for non‑critical parts, standard carbon steels save cost. Recording these decisions clearly prevents ambiguity at procurement and during inspection.

What Role Do Weldability and Machinability Play in Manufacturing?

Weldability and machinability shape manufacturing complexity, inspection needs and overall production cost. Weldability depends on composition (carbon equivalent), required preheat and filler selection — poor weldability increases inspection, distortion control and rework. Machinability affects cycle times and tooling costs; free‑machining carbon grades speed production but may lack required toughness. Mitigations include specifying low‑carbon or controlled‑C variants for welded assemblies or planning a heat‑treat‑after‑machining sequence for hardenable alloys like SAE 4140. Clear fabrication notes in the material spec avoid late‑stage surprises and let shops plan appropriate process controls.

How to Balance Cost-Effectiveness with Material Availability?

Procurement should balance specification fidelity against market realities: confirm mandatory performance metrics, look for performance‑equivalent grades in stock, and request sample certificates and trial pieces before full production. The rules below help strike the balance between cost and availability and set clear conditions for substitution.

- Essential vs. preferred: Flag non‑negotiable properties (impact energy, hardness range) and keep the rest flexible.

- Substitution rules: Allow substitutes only when they meet every essential metric and receive engineering approval.

- Cost‑impact analysis: Evaluate total cost of ownership, including maintenance, downtime and rework.

- Lead‑time governance: Prefer grades readily stocked by multiple suppliers to reduce single‑source risk.

These measures prevent schedule slips and ensure cost savings do not undermine safety or lifecycle performance. If a preferred grade is scarce, consider design adjustments to accept a more available alternative with compensating geometry or process changes.

Which Steel Grades Are Best Suited for Specific Industrial Applications?

Match applications to candidate grades by starting from the primary required properties: shafts and gears need high hardenability and fatigue resistance, structural members prioritise yield and ductility, and marine components demand corrosion resistance. The section below maps applications to recommended grades and highlights typical heat‑treatment and fabrication caveats so you can create shortlists for procurement or testing.

The table links common industrial applications to the key property drivers and example grades used across industry — a quick shortlist for engineering reviews.

| Application | Primary Required Properties | Recommended Grade Examples |

|---|---|---|

| Shafts, axles | High tensile strength, toughness, hardenability | SAE 4140, EN24, EN19 |

| Gears, high-wear parts | High hardness after heat treatment, wear resistance | EN36, EN31, 50CrV4 |

| Structural members | Yield strength, ductility, weldability | IS 2062 E350, IS 2062 E250 |

| Corrosive environments | Corrosion resistance, local formability when required | Stainless family or coated carbon steels |

These recommendations explain typical uses and why a grade’s chemistry and heat‑treatment response make it suitable. Always specify required test values and intended heat treatment to avoid supplier interpretation gaps.

From a bright‑bar supplier perspective: heavy‑duty shafts and high‑strength forgings are commonly supplied as alloy bright bars (SAE 4140, EN24) in round or hex bright‑bar forms ready for machining. For general engineering and structural needs, IS 2062 variants and EN8 are cost‑effective, readily machinable choices. These examples reflect common manufacturing practice and show the bright‑bar stock producers typically hold for industry customers.

What Steel Grades Are Ideal for Automotive and Heavy Engineering?

Automotive and heavy engineering parts demand fatigue strength, toughness and retained properties after heat treatment because components like crankshafts, gears and axles see high cyclic loads. Alloy steels such as SAE 4140 and EN24 are common because Cr–Mo content gives hardenability and a good toughness‑to‑strength ratio after quench and temper. Grades like EN19 and EN36 suit gears and pinions where through‑hardening or case‑hardening, followed by tempering, balances surface wear resistance with a tough core. Always specify heat‑treatment cycles, hardness profiles and NDT acceptance criteria so suppliers and shops deliver parts that meet fatigue life targets.

Which Grades Excel in Construction, Agriculture, and Marine Environments?

Construction and agricultural parts prioritise yield strength, weldability and cost. IS 2062 E250/E350 and EN8‑family steels deliver reliable structural performance and wide availability. In marine or highly corrosive settings, stainless steels or protective coatings are usually essential; where stainless is not feasible, designers commonly use coated carbon steels (galvanised, painted) and design sacrificial layers into the assembly. Specify protective strategy (galvanising, powder coating, cathodic protection) alongside the grade. Local availability and repairability often determine the final choice — selecting grades stocked by regional suppliers reduces downtime and simplifies field maintenance.

How Does Dhand Steels Support Your Steel Grade Selection and Supply Needs?

Dhand Steels manufactures, supplies and exports bright bars and precision metal bars for industrial manufacturing. We offer a broad product range and services that help convert material choices into delivered, ready‑to‑machine stock. Our portfolio includes precision round bars, hex bars, square bars and wire forms for machining and forging operations. We supply alloy bright bars and special‑shaped bars across common industrial grades, and we focus on customer service, tailored finishes and efficient production — all aimed at helping you choose smarter steels for your project.

Our bright‑bar product types and supply features are geared to reduce in‑plant processing and speed production starts. Typical forms and service features you can expect from a specialist supplier like Dhand Steels include:

- Round Bars, Hex Bars, Square Bars: Precision bright bars with machinable finishes for shafts, pins and turned components.

- HHB and HB Wires: Precision wire forms for fasteners and components needing tight diameter control.

- Alloy Steel Bright Bars: Heat‑treatable alloy bars for high‑strength rotating and wear‑resistant parts.

These product forms support manufacturing sectors such as automotive, railways, construction and heavy engineering. We tailor finish, tolerances and heat‑treatment options to customer drawings and machining plans so supplied bars integrate smoothly into production.

What Bright Bar Grades Does Dhand Steels Offer for Industrial Manufacturing?

Our typical bright‑bar offering covers many industry‑recognised grades suitable for industrial use. The list below shows common grade names and the typical forms they serve — a practical starting point for procurement and design teams seeking ready‑to‑machine stock.

- SAE 1018, SAE 1010, SAE 1008: Low‑carbon bright bars for machining and forming.

- EN8, EN8D, EN19, EN24: Medium and high‑strength engineering grades for shafts and forgings.

- SAE 4140, 42CrMo4, 41Cr4: Alloy grades for high‑strength, heat‑treated components.

- IS 2062 E250, IS 2062 E350: Structural grades for construction and fabrication.

- EN31, EN36, SAE 52100, 50CrV4: High‑wear and bearing grades for gears and bearing components.

These grades are available as bright bars in round, hex and square forms and as wire, enabling manufacturers to source ready‑to‑machine stock for diverse industrial applications. Match the delivered grade to your post‑delivery heat‑treatment and machining plan to ensure smooth production integration.

How Do Custom Solutions and Engineering Support Enhance Your Projects?

Working with a supplier that provides engineering support and custom options reduces project risk. Typical support includes specification review, material matching for legacy parts, advice on heat‑treatment routes and surface‑finish recommendations for corrosion or wear control. Custom services — special shapes, tighter tolerances and specified surface finishes — lower downstream machining time and improve first‑pass yield. Post‑sales services such as quality documentation, inspection certificates and production follow‑up help keep schedules predictable and reduce rework, which lowers total project cost and improves product reliability.

What Common Questions Arise When Choosing Steel Grades for Manufacturing?

Engineers and procurement teams often ask how grade choice affects cost, lead time, part life and safety. Short, practical answers help teams make defensible decisions during design reviews. The FAQ below gives actionable guidance and points to where teams should dig deeper.

How Do Steel Grades Affect Manufacturing Project Outcomes?

Grade choice drives schedule, cost and lifecycle outcomes because it determines required fabrication steps (heat treatment, welding preheat), inspection needs and in‑service maintenance. A low‑cost grade that needs frequent protection or replacement can raise lifecycle expense, while a higher‑spec alloy with better fatigue life may increase upfront cost but reduce downtime and warranty exposure. Project teams should quantify trade‑offs by estimating total cost of ownership, required NDT and heat‑treatment steps, and supplier lead times before locking the material spec. Include clear acceptance criteria and test methods in the purchase order to avoid interpretation disputes and keep production on track.

What Are the Strongest and Most Durable Steel Grades for Industrial Use?

There isn’t a single “strongest” steel — strength and durability depend on alloy chemistry, heat treatment and the likely failure mode. High‑strength alloy steels (SAE 4140, EN24) and bearing steels (SAE 52100) deliver high tensile strength and wear resistance when properly heat‑treated. Increasing hardness can reduce toughness and weldability, so specify the required combination of properties (tensile vs impact energy) and the acceptable heat‑treatment route. For safety‑critical or fatigue‑loaded parts, require supplier test certificates and consider pilot tests or fatigue validation before full production.

Frequently Asked Questions

What is the importance of understanding steel grade specifications?

Knowing steel grade specifications ensures the chosen material meets application needs. Each grade carries trade‑offs in strength, ductility and corrosion resistance; misunderstanding those specs can lead to premature failure or avoidable rework. Clear specification lets engineers and buyers select materials that meet safety, longevity and cost targets.

How can environmental factors influence steel grade selection?

Environmental conditions — salt spray, chemicals, temperature cycles — determine whether you need corrosion‑resistant alloys or protective systems. Marine applications usually call for stainless steels or rigorous coatings; high‑temperature parts need alloys that retain strength at operating temperature. Defining the environment up front narrows grade choices and prevents unexpected field failures.

What are the common challenges in procuring the right steel grade?

Common procurement challenges include supply interruptions, limited local availability, and the need for specific certifications. Balancing cost and quality becomes harder when ideal grades are scarce or expensive. Clear specs, good supplier communication and predefined substitution rules help mitigate these issues.

How does heat treatment affect the properties of steel grades?

Heat treatment changes steel microstructure and therefore its strength, hardness and toughness. Quenching and tempering, for example, can raise tensile strength while retaining ductility. Incorrect heat treatment can cause brittleness or unwanted distortion, so specify heat‑treatment cycles and acceptance criteria in your purchase documentation.

What role does cost play in steel grade selection for manufacturing?

Cost is important, but it should be weighed against total cost of ownership. A pricier alloy that reduces downtime and maintenance can be the better economic choice for critical parts. Use lifecycle cost analysis, not just unit price, to choose the best material for the job.

How can custom solutions enhance steel grade selection?

Custom solutions — tailored alloys, tighter tolerances, and specified finishes — can improve manufacturability and reduce downstream work. Suppliers who provide engineering input on grade selection, heat treatment and finishing help optimise parts for performance and cost, improving first‑pass yield and lowering total project risk.

Conclusion

Choosing the right steel grade is a fundamental decision that affects safety, durability and cost. By understanding classification systems, mechanical properties and environmental demands, engineers and procurement teams can make clear, defensible specifications that deliver predictable performance. Partnering with a knowledgeable supplier like Dhand Steels streamlines procurement and provides practical support — from grade selection to finished bright bars — so your production starts clean and stays on schedule. Explore our range of precision steel products to find the right material for your next project.

Comments

0 Comment On Post