Walking ahead with time and initiating the product blend, we will more often than not turn out our lofty removed delicate cast steel Wires, amazingly open across the seas, embellishing our importance and our global mark. Delicate cast steel made Hb Wires are utilized for assembling bike talks, nails, and wires. Out there in loop structure, such wires have at most 480 MPA rigidity. Each curl of such wires weighs 1200 measurement weight units greatest. In the designing field, such wires are utilized as a fundamental piece of pre-pushed and post-tensioning methodology. Offered wires additionally are utilized for creating modern floor, all through the creation of wallboard, etc. Hb Wires are expected for creating radiates for railroad, scaffolds and above the crane.

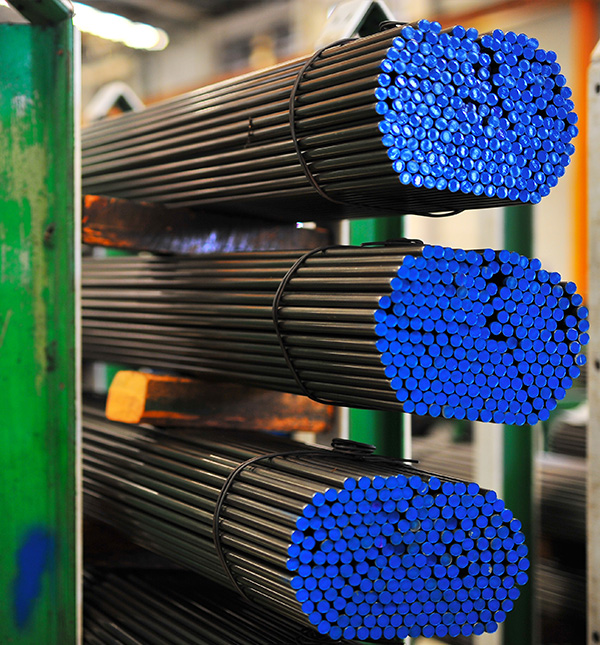

A smooth surface of such wires makes these advantageous to deal with. These are presented with dark treated or electro stirred surfaces to stay away from rust and wear. Ordinarily, such wires have been checked according to their length, surface completion, staple choice, strength, thickness, and fixed life.

The hb wires manufacturer in India shows the wires are provided with remarkable mechanical properties and are appropriate for making the representing pipes and posts, established outlines, etc. These are provided with cutting edge strength and have congruity in various foundation areas. The wires will oppose all weights of the development area and are furnished with fine completion. They’re unaffected by weather conditions and are utilized along the edge of screws, fasteners, nails, and so forth. Given Hb Wires are prepared impervious to rust also as expanded help life. The hb wires manufacturer has claimed Hb Wire Coils are given high-level strength and have utility by and large development circles.

These metal wires are benefited in one in, a couple of crawls to 3 inches, 1 inch to 2 inches size based for the most part choices. Open in specially assembled length, these have the most 1200 measurement weight unit loop weight. Expressed wires are the viewpoint as fundamental components of post-tensioning and pre-pushed philosophies used in designing and substantial construction building positions. To be exact, these hb wires use are required all through the development of wallboard, modern deck radiates for above crane, spans, railroad, and so on. These wires are additionally wont to foster thermal power plants.

Electro excited or dark treated surfaces of such wires are thoroughly worn and rust confirmed. Typical of such wires has been keeping an eye on the possibility of their life span, sort of surface completion, size, strength, opposition credits, thickness, mobility, style, and utility. These wires are cost powerful and have a burr free plan. The smooth surface of such wires decreases the probability of hand injury.

These delicate cast steel wires are drawn through ‘chilly drawing interaction’s abuse steel wire poles, account from the awesome quality staple of our auxiliary organization. Wire Rod is first D-scaled with the help of Double plain descaler hinder delicate scale then the perfect wire bar is handled extra to endure assortment of kicks in the bucket and drums with a middle decrease of 25% to ultimately get through the designated result size and afterward it’s taken in group type of material individual castings.

Procuring upon the innovative speculation with foreknowledge, we keep an eye on our auxiliary and partner organizations who are among the main makers of delicate cast steel wires inside the country. Its yearly capacity is 1.2 creature item metric tons. Trades are on the runway running, with significant pieces of our gift deals ensuring to fire up around the bend.

Determinations of Hb Wire Coil

- Offered wires are profited in one in. to three inches size decisions strength is most 480 MPA.

- The most measured change is six mm.

- Dark treated or electro electrifies surface

Exceptional properties of Hb Wire Coil

Hb Wire is the staple for in quantities of enterprises and items various them are to be specific, for creating Nails, cycle spokes, G.I. wire, Binding wire, Weld network, affixing cathodes, concrete shaft, concrete line, spans, painstaking work, Automobile Spare Parts, screws, Fasteners, Fine Wire, MS Wire, etc.

The items manufactured by Dhand Steels are utilized for various applications as well as binding wire, Gl wire, wire for fencing, armored fixed wire for serious electrical links, Nut fasteners, Nails, screws, and Alpine. Wire ropes. Wire network and so on.

HB wires uses

- Creating 5.0 mm, 5.5 mm, 6.5 mm, 7 mm, 8 mm, and 10 mm size wire rods.

- Wire attracting offices to fabricate Hb Wire of different sizes.

- Use of punching, cutting, and bowing innovation as a piece of creating strategy

- Required all through post-tensioning and pre-focused strategies

- Dependable quality

- Wear confirmation nature

- These exhausting brilliant wires have wide applications in the development field.

- Hb wires are used in enterprises like agribusiness, petrol, car, attaching, fabricating, unit applications, and development. It’s utilized as a staple inside the assembling of items like: Binding wire, weld network, welding cathodes, and so on, and for various purposes comparable to solidifying shafts, concrete lines, extensions, and handiwork instruments. It’s additionally very used in the delivery of nails and cycle spokes.

We, at Dhand Steels, a leading hb wires manufacturer in India notice authentic appreciation across the foundation area, enduring all weights of developments. Such super end solid binding wire and Nails wire are furious for the most part in industry and wire in fencing and a few such styles of HB wires uses.

Comments

0 Comment On Post