EN8D Steel: Practical Guide to Properties, Applications, and When to Choose It Over EN8

EN8D is a medium‑carbon engineering steel valued for its blend of strength, toughness and machinability — a reliable choice for many mechanical parts. This guide breaks down EN8D’s chemistry and mechanical behavior, explains why manufacturers pick it for rotating and load‑bearing components, and compares it with the closely related EN8 grade. Engineers and procurement teams will find practical data on tensile strength, hardness bands, heat‑treatment approaches and international equivalents to guide selection and ordering. We also cover common EN8D uses across automotive, heavy engineering, agriculture and construction, plus guidance on when EN8D outperforms EN8 for wear and service life. Throughout, terms such as EN8D steel uses, EN8D steel properties, EN8D heat treatment and EN8D bright bars are used naturally to aid searchability and decision making.

What are the Key Properties of EN8D Steel?

EN8D is a medium‑carbon grade that delivers good tensile strength and moderate hardenability while remaining reasonably machinable and finishable. Its balanced chemistry and predictable response to heat treatment make it well suited for turned, ground and finished bright bars used in shafts, studs and parts that need controlled hardness. Engineers choose EN8D when they need a cost‑effective mix of strength and wear resistance without moving to alloy steels. Below are two technical tables presenting chemical composition and core mechanical benchmarks to support design and procurement decisions.

What is the Chemical Composition of EN8D Steel?

The table below lists typical element ranges for EN8D and summarizes how each element affects properties and processing. This element → range → practical consequence format helps engineers and buyers set realistic mill tolerances and plan fabrication steps.

| Element | Typical % Range | Effect on Properties |

|---|---|---|

| Carbon (C) | 0.38–0.43 | Raises tensile strength and hardenability; boosts wear resistance but reduces weldability and can make machining more demanding |

| Manganese (Mn) | 0.60–0.90 | Increases strength and hardenability, aids deoxidation and offsets carbon‑induced brittleness |

| Silicon (Si) | 0.10–0.35 | Serves as a deoxidizer and contributes modest strength without significantly harming toughness |

| Phosphorus (P) | ≤ 0.04 | Kept low as an impurity limit — higher P can reduce ductility and fatigue performance |

| Sulfur (S) | ≤ 0.05 | Small amounts can aid machinability; excessive S lowers toughness |

In short, carbon and manganese drive mechanical behavior and hardenability, while silicon and residuals influence machinability and toughness trade‑offs. Knowing these ranges helps you specify acceptable mill tolerances and anticipate challenges like welding or deep hardening.

What are the Mechanical Properties of EN8D Steel?

| Property | Typical Value / Range | Unit / Context |

|---|---|---|

| Tensile strength (UTS) | 580–800 | MPa, depending on heat treatment and cold working |

| Yield strength (0.2% proof) | ~320–520 | MPa, estimated range for normalized vs. as‑rolled conditions |

| Hardness | 170–250 HB (~60–95 HRB) | Brinell/Rockwell values vary with normalization and tempering |

| Density | 7.85 | g/cm³, typical steel density for mass calculations |

| Machinability | Good to fair | Relative to free‑cutting steels; improved by bright‑bar finish and controlled S content |

These benchmarks show why EN8D is chosen for parts needing moderate to high tensile strength with controlled machinability. Always specify final heat‑treatment targets and hardness windows to ensure service life and interchangeability.

How is EN8D Steel Used Across Industries?

EN8D is used across sectors where performance must meet cost constraints — especially when predictable strength, moderate wear resistance and reliable machining finishes are required. Typical industries include automotive, heavy engineering, agriculture, construction, railways and general manufacturing. Bright‑bar formats (round, hex, square) deliver straightness, tight tolerances and surface finish that cut secondary machining and speed assembly. Below are primary uses and the reasons engineers specify EN8D in each area.

- Automotive and heavy engineering: chosen for components where a good strength‑to‑cost ratio and fatigue resistance are important.

- Agricultural equipment: used for linkages and shafts that need wear resistance and easy serviceability in the field.

- Construction and railways: selected for precision parts where consistent dimensional control and straightness matter.

These application points explain why EN8D is often the baseline medium‑carbon grade for parts that require a practical balance of mechanical performance and economical manufacturing. The next sections look closer at specific components and bright‑bar uses.

What are the Common Applications of EN8D Steel in Automotive and Heavy Engineering?

EN8D is widely used for turned and machined parts where tensile strength and wear resistance are needed without the cost of alloy steels. Common components include shafts, gears, axles, light‑duty crankshafts and studs. Its carbon content allows effective surface hardening or through‑hardening with standard heat treatments, improving wear life while keeping a tough core. EN8D bright bars are often specified where parts will be ground and finished to tight tolerances, supporting balanced rotation and reliable service in demanding assemblies.

How Do EN8D Steel Bright Bars Serve Agricultural and Construction Sectors?

In agriculture and construction, EN8D bright bars are used for pins, coupling shafts, linkages and other wear‑prone components that benefit from a smooth finish and accurate dimensions. The bright‑bar process produces straighter bars with better surface condition, cutting secondary machining and improving fit in pivot joints and transmission linkages. EN8D’s machinability and amenability to standard heat treatments let fabricators tailor surface hardness while preserving core ductility, lowering maintenance and total lifecycle cost for field equipment.

What are the Differences Between EN8D and EN8 Steel?

EN8D and EN8 are closely related medium‑carbon steels with many overlapping uses, but small differences in composition and processing limits can change performance for specific parts. The main distinctions usually concern tighter impurity and processing controls on EN8D that influence surface quality, machinability and agreed hardness ranges for bright‑bar specs.

Comparison of EN8D vs EN8:

| Grade | Carbon % | Tensile Strength (typical) | Typical Applications | Notes on Substitution |

|---|---|---|---|---|

| EN8D | 0.38–0.43 | 580–800 MPa | Shafts, studs, light axles, precision bright‑bar components | Preferred where slightly higher carbon and controlled processing enhance wear resistance |

| EN8 | 0.36–0.44 | 540–780 MPa | General engineering components, turned parts, some shafts | Suitable where better weldability or slightly lower hardness is required |

How Do EN8D and EN8 Steel Compare in Chemical Composition and Strength?

EN8D is often specified with narrower tolerances — especially for carbon and manganese — to give reliable hardenability and repeatable hardness after heat treatment. EN8 may permit wider ranges, which can mean slightly lower tensile or hardness extremes but improved weldability. Practically, EN8D usually offers better wear resistance and longer life for sliding or contact surfaces under similar heat‑treatment schedules. For fatigue‑ or wear‑critical parts, choosing EN8D and specifying final hardness and tensile targets lowers the risk of early failure.

Which Applications Suit EN8D Better Than EN8 Steel?

EN8D is better where parts face higher stress or wear and where extra hardenability or a slightly higher carbon content improves life expectancy. Examples include heavy‑duty shafts, ground precision pins in repetitive assemblies and light axles operating in abrasive conditions. In those cases, EN8D’s combination of tensile strength and surface‑hardening response often extends service intervals and reduces maintenance. Where weldability, ductility or notch toughness are the priority, EN8 may be the preferable option.

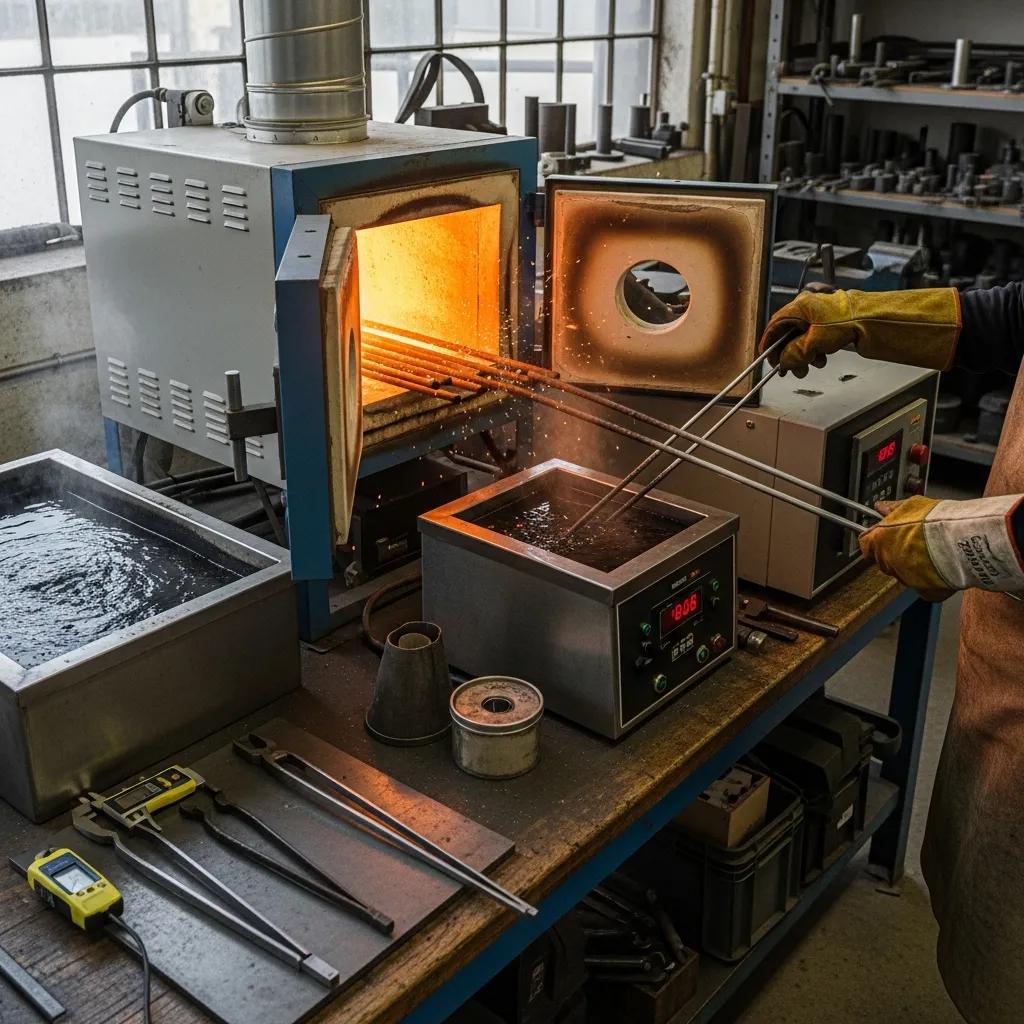

What Heat Treatment Processes Optimize EN8D Steel Performance?

Heat treatment tailors EN8D’s microstructure so you can hit the right mix of hardness, toughness and machinability. The three main processes — normalizing, hardening (quenching) and tempering — are commonly used on EN8D bright bars depending on the final requirement. Each step alters grain structure and residual stress; controlling temperatures, soak times and cooling media lets you refine grain size, boost toughness or raise surface hardness as needed. The following subsections explain normalizing and then offer practical hardening and tempering guidance for shop floors and engineering specs.

How Does Normalizing Affect EN8D Steel Properties?

Normalizing refines EN8D’s grain structure by heating above the critical range and air‑cooling to form a uniform ferrite‑pearlite microstructure. Typical normalizing temperatures for medium‑carbon steels like EN8D are around 830–860°C, followed by air cooling. This reduces internal stresses from rolling, improves homogeneity and gives a stable baseline hardness suitable for turning and grinding before final heat treatment. Shops often prefer normalizing over full anneal when they need quicker cycles and less scale with acceptable machinability.

What are the Hardening and Tempering Procedures for EN8D Steel?

Hardening EN8D means austenitizing roughly between 820–860°C, then quenching in oil or water depending on section size and desired hardness — oil quench is common for medium sections to reduce cracking and distortion. Quenching produces a martensitic structure that is then tempered (typically between 250–650°C) to balance hardness and toughness: lower tempering temperatures preserve higher hardness, while higher tempering improves toughness and reduces brittleness. Key cautions: control section thickness, avoid overly severe quenching that causes distortion, and consider staged tempering when dimensional stability and fatigue resistance are critical.

What are the Equivalent Grades and Standards for EN8D Steel?

EN8D closely maps to several international medium‑carbon grades such as AISI 1045, S45C, C45 and 080M40, though exact substitution depends on the required mechanical criteria and allowable chemical differences. When cross‑referencing, compare both composition ranges and guaranteed mechanical properties rather than relying only on grade names. The table below maps EN8D to common equivalents and highlights substitution caveats for procurement and QA.

| EN8D Equivalent | Common Designation | Notes on Equivalence |

|---|---|---|

| AISI 1045 | 1045 | Similar carbon level; verify mill tensile and hardness guarantees when substituting |

| S45C / C45 | S45C / C45 | Closely comparable; confirm bright‑bar finish and impurity limits meet your spec |

| 080M40 | 080M40 | European designation with similar medium‑carbon traits; check mechanical guarantees before interchange |

Which International Steel Grades are Equivalent to EN8D?

Practical equivalents include AISI 1045, S45C (JIS), C45 (DIN/EN contexts) and 080M40 in some European specs. These grades share medium‑carbon chemistry and heat‑treatment responsiveness, allowing many designs to move between supplier catalogs. Small differences in impurity limits (P, S) and mill processing can affect machinability and fatigue behavior, so always specify final mechanical testing or hardness windows when ordering equivalents to ensure performance parity.

How Does EN8D Steel Align with Industry Standards like BS and IS?

EN8D is often referenced against British and Indian medium‑carbon bright‑bar standards. For procurement or QA documents, include both the grade and required acceptance criteria such as tensile range, yield and maximum hardness. Clear procurement phrasing — for example, “EN8D bright bars, ground, hardness 180–230 HB, normalized” — reduces ambiguity and avoids unwanted substitutions. Use standard codes as a baseline while specifying critical properties to ensure compatibility with fabrication and downstream performance.

After reviewing equivalents, buyers can evaluate product forms and mill capabilities. Dhand Steels supplies EN8D in standard bright‑bar formats (round, hex, square) with precision straightness and finishes suited to turned and ground components. To get product details or a tailored quote for EN8D bright bars in your required dimensions and finish, request a quotation that lists the grade and desired mechanical targets.

Why Choose Dhand Steels for EN8D Steel Bright Bars?

We supply and export high‑precision bright bars, including EN8D and EN8, to customers across India and overseas. Our focus is on bright‑bar straightness and surface finish, a broad grade range to meet engineering specs, and cost‑effective manufacturing for production buyers. We also emphasize energy efficiency and responsive post‑sales support to help reduce lifecycle costs. Below are the supplier advantages and product details to help technical purchasers assess fit for their applications.

What makes Dhand Steels an appropriate supplier:

- Precision bright bars: excellent straightness and tight dimensional tolerances that cut secondary machining and improve assembly fit.

- Wide grade range and product forms: EN8D and related grades available in round, hex and square bright bars.

- Cost‑effective industrial solutions: manufacturing optimized to balance consistent quality with competitive pricing for production volumes.

These strengths make Dhand Steels a good match for manufacturers specifying EN8D for shafts, studs and components where predictable mechanical performance and efficient machining matter. When requesting quotes, specify grade, bar form and final mechanical acceptance limits to ensure the supply meets your needs.

What Quality and Sustainability Advantages Does Dhand Steels Offer?

Our quality controls focus on precision straightening and consistent bright‑bar surfaces, while process improvements target lower carbon emissions and better energy efficiency. We combine process optimization with post‑sales technical support and customization services to meet specific requirements. These QA and sustainability efforts help procurement teams meet internal targets while securing a dependable supply of EN8D and other medium‑carbon grades.

What Product Forms and Post-Sales Services Does Dhand Steels Provide?

Dhand Steels supplies EN8D in common bright‑bar forms — round, hex and square — suited to turning, grinding and precision assembly. Post‑sales services include technical guidance on material selection, customization for non‑standard shapes and export logistics for international buyers. Request a quote with grade, dimensions and desired heat‑treatment or finish to receive a matched commercial offer and lead‑time estimate.

- Product Forms: round, hex and square bright bars supplied to precision machining and assembly standards.

- Customization: technical support for custom shapes and tighter tolerances for specialized components.

- Post-sales Support: QA assistance and export‑ready logistics for domestic and international orders.

These capabilities complement the technical guidance above, helping engineers and procurement teams convert specification choices into clear purchase requests and supplier conversations.

Frequently Asked Questions

What are the advantages of using EN8D steel over other medium-carbon steels?

EN8D offers a practical balance of strength, toughness and machinability. Its controlled carbon and manganese levels deliver improved wear resistance and hardenability compared with many medium‑carbon steels, which can extend component life in contact or sliding applications. At the same time, EN8D’s machinability helps reduce processing time and cost — an advantage in high‑volume production.

How does the heat treatment process affect the performance of EN8D steel?

Heat treatment strongly influences EN8D’s mechanical properties. Normalizing refines grain size and improves dimensional stability and machinability. Hardening (quenching) raises surface hardness and wear resistance, and tempering adjusts the balance between hardness and toughness. Selecting temperatures, quench media and tempering cycles lets manufacturers tailor EN8D for specific service conditions while managing distortion and fatigue performance.

What are the typical dimensions and tolerances for EN8D bright bars?

EN8D bright bars come in round, hex and square shapes, commonly from about 10 mm to 100 mm in diameter or equivalent sizes. Precision bright bars can achieve tolerances around ±0.1 mm or better depending on the process. Such dimensional accuracy is essential for tight‑fit components in automotive and heavy engineering applications.

Can EN8D steel be welded, and what precautions should be taken?

Welding EN8D is possible but needs care because medium carbon content increases the risk of reduced ductility or brittleness in the heat‑affected zone. Typical precautions include preheating, using suitable filler material and, when necessary, performing post‑weld heat treatment. Evaluate the specific application and service environment before welding to select the correct procedure.

What factors should be considered when selecting EN8D for a specific application?

Consider required mechanical properties (tensile strength, hardness, wear resistance), operating environment, and intended manufacturing processes. Plan any heat treatment and final machining steps in advance, and specify acceptance criteria such as hardness windows or tensile ranges to ensure the delivered material meets performance needs.

How does the cost of EN8D compare to other steel grades?

EN8D is generally cost‑competitive versus higher‑alloy steels, offering a good performance‑to‑price ratio. Although its unit cost may be higher than very low‑grade steels, the improved wear resistance and longer service life of EN8D components can reduce total lifecycle costs, making it an economical choice for many industrial applications.

Conclusion

EN8D is a dependable medium‑carbon grade when you need a balance of strength, toughness and machinability across multiple industries. Its controlled hardenability and wear resistance make it a strong candidate for critical rotating and load‑bearing parts. By understanding EN8D’s properties, heat‑treatment options and equivalents, engineers can specify parts that meet performance and cost targets. For detailed product options or a tailored quote on EN8D bright bars, contact our team — we’ll help match the material and finish to your application.

Comments

0 Comment On Post