SAE 1030 Steel — Practical Guide to Properties, Applications and Engineering Uses

SAE 1030 is a medium‑carbon steel grade commonly chosen where a reliable mix of strength, ductility and machinability matters. This guide lays out SAE 1030’s material definition, chemistry, and how that chemistry produces a ferrite–pearlite microstructure that delivers predictable tensile performance while remaining reasonably weldable and cold‑workable. Engineers and buyers will find clear ranges for composition, mechanical and physical benchmarks, typical applications, and practical heat‑treat and fabrication advice to get the most from the grade. We also map international equivalents, compare SAE 1030 with nearby grades, and close with supplier considerations for specifying bright bars or round bars. Keywords such as SAE 1030 steel properties, SAE 1030 material and SAE 1030 carbon steel composition are used thoughtfully to support selection and manufacturing decisions.

What is SAE 1030 Steel? Definition and Chemical Composition

SAE 1030 is a medium‑carbon engineering steel defined by its nominal carbon level and balanced minor alloying for general mechanical use. Carbon typically sits around 0.28–0.33% and manganese is added to boost strength and hardenability, while phosphorus and sulfur are kept low to protect toughness and machinability. In the as‑rolled or normalized condition this chemistry produces a ferrite matrix with a significant pearlite fraction, giving tensile strength suitable for shafts and axles and a predictable response to standard heat treatments. Knowing the element ranges helps engineers anticipate heat‑treatment behavior and match processing to part performance.

The table below gives a machine‑readable summary of the chemical composition for quick reference and specification writing.

This table lists the main element ranges for SAE 1030 and explains their primary roles.

| Element | Typical Range (wt%) | Function / Effect |

|---|---|---|

| Carbon (C) | 0.28 – 0.33 | Raises strength and hardness; increases hardenability; reduces ductility as content rises |

| Manganese (Mn) | 0.60 – 0.90 | Increases tensile strength and hardenability; offsets sulfur effects |

| Phosphorus (P) | ≤ 0.040 | Tightly controlled impurity — excess reduces toughness |

| Sulfur (S) | ≤ 0.050 | Small amounts aid machinability; higher levels harm ductility |

| Iron (Fe) | Balance | Primary matrix metal that hosts alloying elements and microstructure |

Use this composition table when preparing purchase specifications and traceability documentation.

What elements make up SAE 1030’s chemical composition?

SAE 1030’s key constituents are carbon, manganese, phosphorus, sulfur and iron. Carbon is the main strength influencer — the 0.28–0.33% range allows moderate hardening by quench and temper while keeping workable ductility for forging and forming. Manganese (≈0.6–0.9%) improves tensile strength and hardenability and compensates for trace impurities. Phosphorus and sulfur are controlled to preserve toughness; small, managed sulfur can help machinability, but SAE 1030 generally prioritizes balanced toughness. Understanding each element’s role helps designers predict processing windows and final part behavior.

That element‑by‑element view naturally leads into how composition translates to material performance and processing outcomes.

How does chemical composition affect SAE 1030 steel properties?

The alloying profile determines SAE 1030’s microstructure and therefore its strength, toughness, machinability and heat‑treatment response. Higher carbon increases pearlite fraction in the ferrite matrix, boosting strength and hardness but lowering elongation and impact toughness. Manganese raises strength and hardenability with a smaller ductility penalty than carbon. Low phosphorus and sulfur help maintain toughness and fatigue resistance; uncontrolled impurities create stress concentrators and lower reliability. In practice, SAE 1030 is suited to parts needing moderate strength with good fatigue life and responds predictably to anneal, normalize and quench‑and‑temper cycles when these are built into the process.

Knowing these composition–property links explains why designers choose SAE 1030 instead of lower‑ or higher‑carbon alternatives for many applications.

What are the Mechanical and Physical Properties of SAE 1030 Steel?

SAE 1030’s mechanical and physical properties depend on processing history, but normalized or annealed values provide reliable baselines for design. In normalized condition the grade typically shows mid‑range tensile and yield strengths suitable for shafts, axles and connecting rods. Hardness and elongation vary depending on whether material is as‑rolled, normalized or quenched and tempered. Understanding these ranges and how heat treatment shifts them is essential for specifying machining allowances, surface treatments and safety factors.

The table below summarizes common mechanical and physical benchmarks used in engineering calculations and material selection.

| Property | Typical Range / Value | Notes |

|---|---|---|

| Tensile strength (UTS) | 540 – 670 MPa | Depends on heat treatment; normalized often near 540–620 MPa |

| Yield strength (0.2% offset) | 370 – 460 MPa | Processing dependent; lower in annealed state |

| Elongation (A%) | 12 – 20% | Shows good ductility for a medium‑carbon steel |

| Hardness (HB) | 170 – 230 HB | As‑rolled/normalized; higher after quench and temper |

| Density | ~7,850 kg/m³ | Standard carbon‑steel density used for mass/inertia calculations |

What tensile, yield and hardness values should I expect from SAE 1030?

Values vary with thermal and mechanical history. Normalized SAE 1030 commonly shows tensile strengths around 540–620 MPa and yield strengths in the 370–450 MPa range. Hardness in annealed or normalized states typically falls between 170 and 230 HB; quench‑and‑temper can increase both hardness and strength while reducing ductility. Reported numbers assume standard room‑temperature tensile tests per ASTM‑type methods, so specify heat‑treatment condition and test standard when ordering. Tempering temperature after quenching is the primary control for the strength‑vs‑toughness trade‑off.

Next we cover the physical constants that affect stiffness, thermal response and weight calculations.

What physical properties characterize SAE 1030 (density, thermal conductivity, etc.)?

SAE 1030 shares typical carbon‑steel constants: density ≈ 7,850 kg/m³, elastic modulus ≈ 210 GPa, and Poisson’s ratio ≈ 0.27–0.30. Thermal conductivity and specific heat affect heat‑treatment cycle design and cooling rates during quenching; SAE 1030’s thermal behaviour is typical of carbon steels and supports predictable heat extraction in common quench media. These properties matter for dynamic components because stiffness controls deflection and vibration, while thermal properties influence distortion risk during processing. Account for these constants when sizing parts and specifying fixtures or quench parameters for production runs.

Combining mechanical benchmarks with physical constants enables accurate finite‑element and thermal simulations before production.

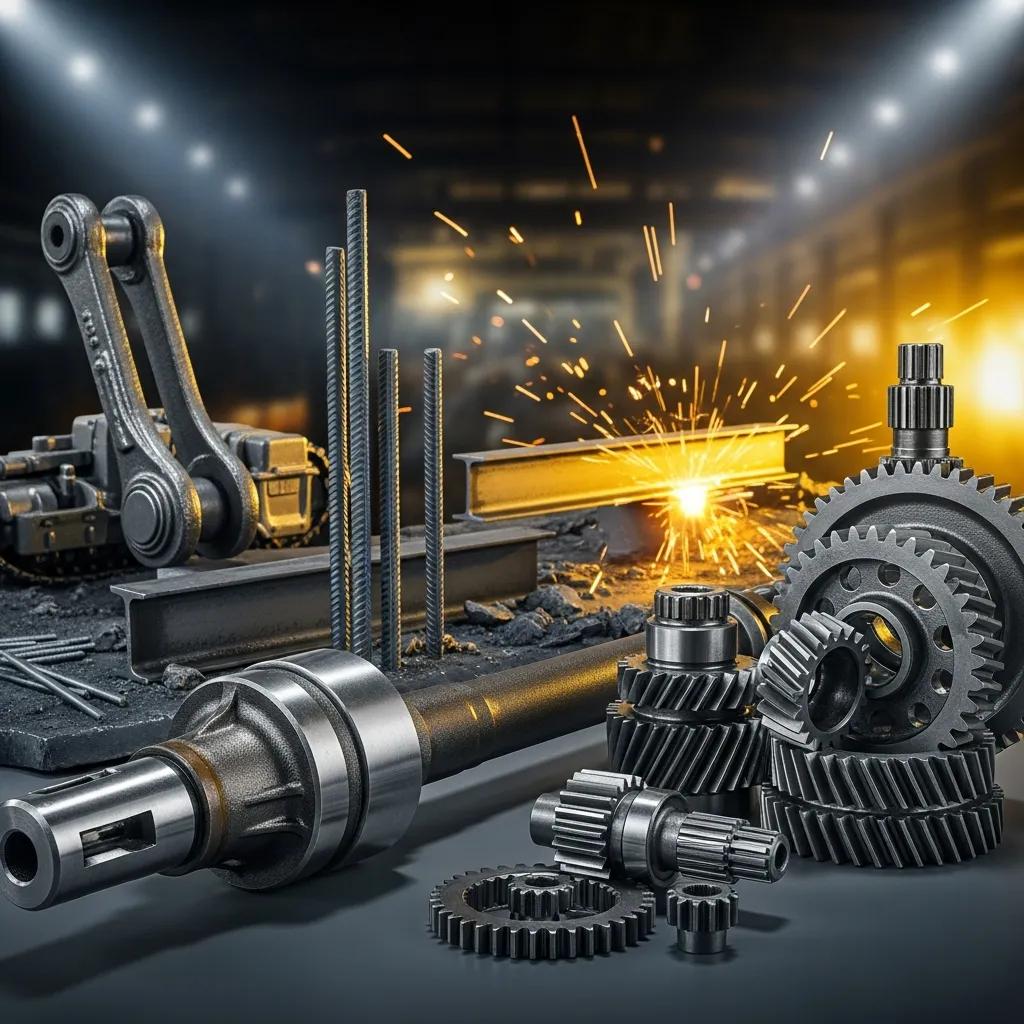

What are the Key Applications of SAE 1030 Steel Across Industries?

SAE 1030’s balance of strength, ductility and cost makes it a go‑to medium‑carbon steel across automotive, machinery, construction, agriculture and rail industries. It’s selected where moderate hardenability and post‑processing (turning, grinding, heat treating) produce fatigue‑resistant, machinable parts without the cost of high‑alloy steels. Designers choose SAE 1030 when parts need toughness and the ability to accept surface hardening or quench‑and‑temper treatments for bearing or contact surfaces.

- Rotating parts in automotive and machinery where strength and fatigue resistance matter.

- Structural and agricultural components that need durability at a competitive cost.

- Rail and heavy engineering parts requiring predictable toughness and weldability.

These application groups explain why SAE 1030 remains widely used for medium‑duty mechanical components and infrastructure parts.

How is SAE 1030 used in automotive and machinery components?

In automotive and machinery applications SAE 1030 is commonly used for shafts, axles, gears (after correct heat treatment), connecting rods and other turned or ground parts that demand surface integrity and fatigue resistance. Machined parts often begin as bright or round bars to reduce machining allowances and maintain concentricity; precision straightening and a good surface finish cut cycle times in turning and grinding. Where surface wear is a concern, selective hardening or quench‑and‑temper gives a hard running surface with a tougher core. Specifying the right supply form and pre‑processing reduces downstream machining and inspection work.

These practical uses tie into SAE 1030’s roles outside automotive and machinery sectors.

What roles does SAE 1030 play in construction, agriculture and railways?

In construction and agriculture, SAE 1030 is often specified for axles, pins, couplers, spindles and fastening parts where a balance of strength, ductility and cost is required. Rail and heavy engineering use it for non‑critical structural items, couplings and components that can be welded and thermally processed as needed. Exposure to corrosion and repeated loading in these sectors means designers often add coatings, controlled heat treatments or surface finishes to extend life. Ready machinability and availability in bright or round bar forms make SAE 1030 convenient for fabricators running production batches.

With applications established, the next focus is processing and heat treatment to achieve the required properties.

How is SAE 1030 Steel Processed and Heat Treated for Optimal Performance?

Processing and heat treatment determine the final performance of SAE 1030 parts. Common routes include annealing for improved machinability, normalizing for grain refinement and quench‑and‑temper for higher strength and fatigue resistance. Choose anneal, normalize or quench‑and‑temper based on the desired balance of hardness, toughness and dimensional stability after machining. Cycle control and quench‑media selection are important because SAE 1030’s medium carbon and moderate hardenability affect distortion and residual stress during rapid cooling.

- Annealing: Softens material for easier machining and reduces internal stress before forming.

- Normalizing: Refines grain structure for improved toughness and a uniform microstructure.

- Quench & Temper: Increases strength and hardness by quenching, then tempers to restore ductility.

What heat treatment methods apply to SAE 1030?

Annealing (heat to austenitize then slow cool) lowers hardness and improves machinability prior to extensive turning or forming. Normalizing (air cool from austenitizing temperature) yields a finer ferrite/pearlite microstructure and better toughness than as‑rolled stock. Quench and temper (austenitize, quench in oil or water depending on section size, then temper at the required temperature) raises hardness and strength; temper temperature controls the strength‑toughness balance. SAE 1030’s moderate carbon limits hardenability compared with higher‑carbon steels, so large sections may not through‑harden without higher quench severity or appropriate pre‑heating practices.

This heat‑treat overview leads into practical fabrication guidance for forging, welding and cold working.

What should be considered for forging, welding and cold working SAE 1030?

SAE 1030 forges and hot‑works readily at standard temperatures, with working ranges chosen to avoid grain coarsening and to maintain good flow lines. Welding normally succeeds with suitable preheat and controlled interpass temperatures; moderate carbon means preheat reduces cracking risk and post‑weld stress relief can be specified for critical parts. Cold working is possible but expect increased yield strength and some springback; machining from bright bars often avoids heavy cold forming in many designs. When ordering, consider material prepared for downstream processing — straightened bright bars with controlled straightness and traceable quality reduce scrap and process variability.

Dhand Steels supplies SAE 1030 as precision bright and round bars prepared for downstream heat treatment, with straightening tolerances and mill certificates to support processing decisions.

What are the Equivalent Grades and International Standards for SAE 1030 Steel?

SAE 1030 maps to several international designations that simplify global procurement and specification alignment. Cross‑references let engineers specify local standards while preserving the intended chemical and mechanical behaviour. Clear cross‑references reduce specification errors and speed supplier qualification.

| Standard System | Equivalent Grade / Code | Note |

|---|---|---|

| AISI / SAE | AISI 1030 / SAE 1030 | Direct AISI/SAE equivalent |

| UNS | UNS G10300 | Unified Numbering System cross‑reference |

| JIS | S45C | Approximate Japanese equivalent |

| DIN / EN | C35E (1.0503) | European designation with similar carbon content |

| IS / GOST | 35G (GOST 1050) | Local standards may vary slightly in tolerances |

Which international standards correspond to SAE 1030?

Common cross‑references include AISI 1030 and UNS G10300; JIS and DIN/EN systems use codes such as S45C and C35E for similar medium‑carbon chemistries. Standards differ in tolerances and test requirements, so always cite the exact document (ASTM, JIS, EN, etc.) when writing specifications to ensure test methods and acceptance criteria match. Use the cross‑reference table as a starting point, but include chemical limits, mechanical targets and required mill certificates in final purchase specs.

Knowing equivalence helps compare mechanical expectations and sourcing options between suppliers across regions.

How does SAE 1030 compare to other medium‑carbon steels like 1018 and 1045?

Compared with 1018 (low‑carbon steel), SAE 1030 contains more carbon and therefore offers higher strength and improved hardenability; 1018 is easier to cold‑form and weld but cannot reach the same hardness. Versus 1045, SAE 1030 has less carbon so it achieves lower maximum hardness and strength after quench‑and‑temper, but it’s more machinable and less prone to weld cracking. Choose based on required final hardness, toughness, weldability and cost: 1018 for ease of forming and welding, 1030 for balanced strength and machinability, 1045 for higher strength where greater hardenability is needed. This framework helps match grade to part geometry, heat treatment and production constraints.

With equivalence and comparisons clear, we now turn to supplier selection and production readiness considerations.

Why Choose Dhand Steels for SAE 1030 Bright Bars and Solutions?

Dhand Steels supplies bright bars and specialty shaped bars suitable for medium‑carbon grades like SAE 1030. For procurement teams needing reliable material for turned, ground and heat‑treated components, we offer precision bright and round bars plus the documentation and traceability required for engineering qualification. We serve manufacturing, agriculture, automotive, railways, construction and heavy engineering sectors and focus on cost‑effective supply with quality control practices that reduce downstream variability.

Dhand Steels emphasizes practical benefits that align with engineering needs and sustainability goals:

- Precision straightened bright bars that reduce machining setup time and scrap during turning and grinding.

- Material certificates and traceability to support incoming inspection and compliance.

- Work toward lower‑carbon “smarter steels” to help customers improve supply‑chain sustainability.

These capabilities make Dhand Steels a strong choice when specifications call for SAE 1030 bright bars with documented quality and predictable processing behaviour.

What advantages do Dhand Steels’ bright bars offer for SAE 1030 applications?

Engineers specifying bright bars for shafts, axles and turned parts value surface finish, straightness and dimensional tolerances. Dhand Steels focuses on precision straightening and reduced surface defects to minimize pre‑machining work. That reduces material removal to reach final diameters and concentricity, and a consistent surface finish supports better fatigue performance in rotating parts. Robust QA and traceability lower procurement risk by supplying the documentation needed for audits and compliance. Together, these benefits shorten cycle times, cut rejects and improve process control in machining and heat‑treat workflows.

This benefit summary is consistent with our sector focus across automotive, rail and heavy engineering applications.

Are there case studies showing Dhand Steels’ experience with SAE 1030?

Dhand Steels has supported manufacturing and heavy‑engineering projects by supplying medium‑carbon bright and round bars tailored for downstream machining and heat treatment. Typical engagements start with customer issues like excessive machining allowance or variable incoming hardness; we respond with straightened bright bars and documented composition and finish, reducing scrap and improving cycle times in turning and grinding. The resulting outcomes — less rework, consistent hardenability after quench and temper, and traceable documentation — show how matched material supply improves manufacturing efficiency. Procurement teams seeking supplier qualification or a quote can contact Dhand Steels to discuss specs, mill certificates and available product forms.

For engineers and buyers specifying SAE 1030 bright bars, Dhand Steels offers a supplier profile aligned with medium‑carbon steel needs and production realities.

Frequently Asked Questions

What are the benefits of using SAE 1030 steel in manufacturing?

SAE 1030 offers a balanced mix of strength, ductility and machinability, making it suitable for many manufacturing parts. Its medium carbon content allows moderate hardenability, which helps when fatigue resistance and toughness are needed. The grade responds predictably to heat treatments such as quench and temper, giving engineers flexibility to meet performance targets while keeping material costs reasonable.

How does heat treatment change SAE 1030’s properties?

Heat treatment has a strong effect on SAE 1030. Annealing softens the steel for machining, normalizing refines grain structure and improves toughness, and quench‑and‑temper increases hardness and strength while tempering restores ductility. The right heat‑treat cycle depends on the balance of hardness, toughness and dimensional stability required for the part.

What common welding challenges exist with SAE 1030?

Welding SAE 1030 can be more demanding than low‑carbon steels because of its medium carbon content, which raises the risk of hardening and cracking in the heat‑affected zone. Preheating and controlled interpass temperatures are recommended to reduce cracking risk, and post‑weld stress relief may be required for critical applications.

In what forms is SAE 1030 typically supplied?

SAE 1030 is commonly supplied as bright bars, round bars and other shapes suited to specific applications. Bright bars are preferred when surface finish and dimensional accuracy matter because they reduce machining allowances and improve production efficiency. These supply forms are often prepared to support downstream machining and heat treatment.

How does SAE 1030 compare to other medium‑carbon steels on cost and performance?

SAE 1030 balances cost and performance between lower‑carbon and higher‑carbon steels. Compared with 1018, it offers higher strength and hardenability but is less easy to form and weld. Compared with 1045, it is more machinable and less prone to weld cracking but cannot reach the same peak hardness after quench and temper. SAE 1030 is a common compromise when you need good strength and machinability at a competitive price.

What should I consider when selecting SAE 1030 for a project?

Key considerations include the required mechanical properties, the intended application, and the manufacturing steps (machining, heat treatment, welding). Evaluate the needed balance of strength, ductility and machinability, and specify heat‑treatment and testing criteria in the purchase order. Also consider cost and availability in the required supply form to ensure project feasibility and consistent production quality.

Conclusion

SAE 1030 offers a reliable combination of strength, ductility and machinability that fits many engineering applications. Its predictable response to heat treatment makes it straightforward to specify and process for parts that require balanced performance. By understanding its chemistry, properties and common uses—and by choosing a supplier that provides documented, properly prepared bright bars—you can reduce rework and improve production efficiency. Explore our SAE 1030 product range to find the right bright or round bar for your manufacturing needs.

Comments

0 Comment On Post