When sourcing steel for engineering or manufacturing projects, the choice often comes down to specific material properties. Two common options are bright bars and standard carbon bars. While both originate from similar base materials, their differences in processing, finish, and application are significant. As one of the premier bright bars suppliers India relies on, Dhand Steels has deep expertise in helping clients choose the perfect material for their needs. This guide will compare these two essential products to help you make an informed decision before placing your next order.

What Are Carbon Bars? The Foundational Material

Carbon steel bars, often called black bars or hot-rolled bars, are the starting point for many steel products. They are manufactured by heating steel billets and passing them through rollers to achieve the desired shape and size. This hot-rolling process leaves a scaly, dark surface finish.

The primary characteristics of standard carbon bars include:

- Good Strength and Durability: They form the backbone of countless structural and manufacturing applications.

- Workability: They are easily welded and machined, although they may require more finishing work.

- Cost-Effectiveness: Their simpler manufacturing process makes them an economical choice for general-purpose use.

These bars are the workhorses for applications where surface finish and tight dimensional tolerances are not the main priorities. For a full overview of our foundational steel materials, you can explore the Dhand Steels products page. For specific inquiries about grades for projects in Maharashtra or Gujarat, our team is ready to assist. You can reach them at solutions@dhandsteels.com.

What Are Bright Bars? The Precision Product

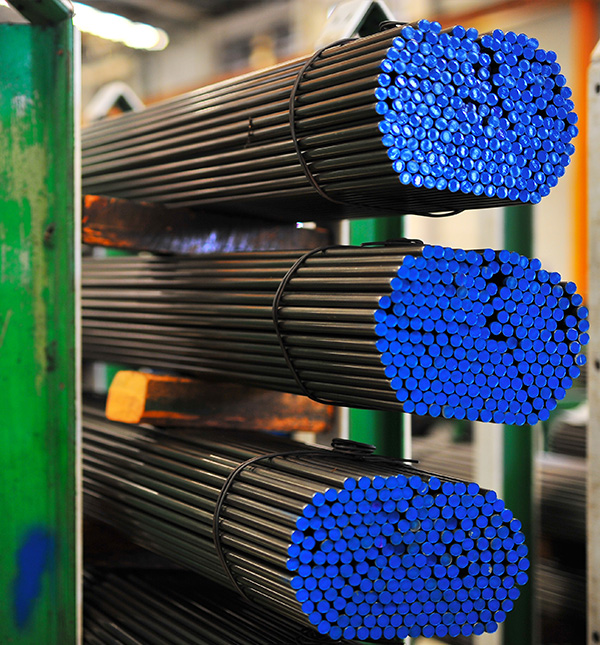

Bright bars are not a different type of steel but rather a value-added product made from carbon steel bars. They undergo secondary processing—such as cold drawing, peeling, or grinding—to achieve a superior surface finish and exceptional dimensional accuracy. This process removes the imperfections and scale left from hot rolling.

Key features of bright bars include:

- Superior Surface Finish: A smooth, bright, and clean surface that often requires no further polishing.

- Tight Dimensional Tolerances: Extremely precise diameters and straightness, crucial for automated machining.

- Enhanced Mechanical Properties: The cold drawing process increases the steel’s tensile strength and hardness.

This precision makes bright bars the ideal choice for high-end applications where fit, finish, and performance are critical. For a quote on your bright bar requirements, you can connect with us instantly via our WhatsApp link.

[Image: A CNC machine precisely cutting a bright bar into a complex automotive component.]

Alt text: A CNC machine demonstrating why top bright bars suppliers India, like Dhand Steels, are essential for precision manufacturing.

Finding Reliable Bright Bars Suppliers India

For engineers in Tamil Nadu and Karnataka, sourcing consistent quality is paramount. The reliability of bright bars suppliers India has on offer can make or break a production line. Dhand Steels ensures every bright bar meets stringent quality standards, providing the consistency needed for high-volume manufacturing for clients in the USA and Germany. This is why procurement teams trust us for their critical supply needs.

Key Differences: A Head-to-Head Comparison

| Feature | Standard Carbon Bars | Bright Bars |

| Surface Finish | Scaly, dark, rough surface | Smooth, polished, bright surface |

| Dimensional Tolerance | Loose tolerances | Very tight, precise tolerances |

| Manufacturing Process | Hot rolling | Cold drawing, peeling, or grinding |

| Mechanical Properties | Standard strength and hardness | Higher tensile strength and hardness |

| Common Applications | General fabrication, structural use | CNC machining, automotive shafts, precision fasteners |

| Cost | More economical | Higher initial cost due to additional processing |

This table clearly illustrates why bright bars are preferred for high-precision jobs. If you need to discuss which material is best for your specific application, please call our technical experts at +91-6283-838-475.

Dhand Steels: Leading Bright Bars Suppliers India

Our commitment to quality is evident in our state-of-the-art manufacturing facility. Located at Unit-I: Plot # 30, Guru Gobind Singh Industrial Enclave, vill. Umedpur, Sahnewal Dehlon Road, Sahnewal, Ludhiana, our plant is equipped to produce world-class bright bars for demanding industries. As leading bright bars suppliers India has, we serve clients in West Bengal and export to markets like Italy, Japan, and the UAE. You can easily find our location on Google Maps.

When to Choose Bright Bars Over Carbon Bars

Choose bright bars when your project demands:

- High-Speed Machining: The clean surface and tight tolerances are perfect for CNC machines, reducing tool wear and improving efficiency.

- Aesthetic Appearance: For components where the final look is important, the polished finish of a bright bar is a major advantage.

- Precision Fit: In applications like automotive shafts or hydraulic fittings, the exact dimensions of bright bars ensure a perfect fit.

For a deeper conversation about our capabilities and how we can meet your export requirements, contact Nikhil Dhand directly at nikhil.dhand@dhandsteels.com. Our expertise as one of the top bright bars suppliers India offers ensures you get the right product every time. For any immediate consultation, feel free to call us at +91-7814-705-181. We’re here to help you succeed.

Frequently Asked Questions (FAQs)

1. What is the main difference between a bright bar and a carbon bar?

The main difference is the finish and dimensional accuracy. A bright bar is a carbon bar that has undergone secondary processing (like cold drawing) to create a smooth surface and tight tolerances, whereas a standard carbon bar has a rough, scaly finish from hot rolling.

2. Are bright bars stronger than carbon bars?

Yes. The cold work process used to create bright bars increases the material’s tensile strength and hardness, making them mechanically stronger than their hot-rolled counterparts of the same grade.

3. Why should I choose Dhand Steels as my bright bars supplier in India?

As experienced bright bars suppliers India trusts, Dhand Steels guarantees superior quality, consistent dimensional accuracy, and a reliable supply chain for both domestic and international clients.

4. What industries typically use bright bars?

Bright bars are extensively used in the automotive industry (for shafts, axles), heavy machinery, fastener manufacturing, and any application requiring high precision and a superior surface finish. Explore our products page for more details.

5. Can I get a custom size or grade of bright bar from Dhand Steels?

Absolutely. We work with clients to provide custom solutions tailored to their specific engineering needs. Contact our team at solutions@dhandsteels.com to discuss your requirements.

6. Do you supply both bright bars and standard carbon bars?

Yes, Dhand Steels offers a comprehensive range of both standard carbon steel bars and precision-finished bright bars to cater to all types of manufacturing and fabrication needs.

7. How can I place an order with Dhand Steels?

You can place an order by calling us at +91-6283-838-475 or by sending an inquiry through our website. Our sales team will assist you promptly.

Comments

0 Comment On Post