20MnCr5 Steel — Composition, Applications and Performance Benefits for Industrial Use

20MnCr5 is a low‑carbon, case‑hardening alloy designed to give a wear‑resistant surface while keeping a tough, ductile core. The grade accepts added carbon at the surface during carburizing, creating a hard case and a resilient core — a practical combination for parts exposed to contact fatigue and impact. This article explains the chemistry that drives 20MnCr5’s behavior, presents the mechanical data engineers depend on, describes common heat‑treatment routes, and outlines applications across automotive, heavy machinery and agriculture. We also compare 20MnCr5 with related grades, summarize key process parameters for carburizing, quenching and tempering, and offer guidance on sourcing bright bars with tight dimensional and surface control. After reading, you’ll have specification‑level clarity, selection criteria for grade choice, and practical tips for procuring 20MnCr5 bright bars from reliable suppliers.

What is the Chemical Composition of 20MnCr5 Steel?

20MnCr5 is characterised by a low base carbon with controlled additions of manganese and chromium to improve hardenability and wear resistance after case‑hardening. This balance lets the carburized surface reach high hardness while the low‑carbon core retains toughness, lowering the risk of brittle failure under cyclic loading. Below is a compact elemental breakdown showing typical ranges and the metallurgical role of each element so engineers can link composition to processing and expected performance. Understanding these influences explains why 20MnCr5 responds reliably to carburizing and tempering, and sets up the processing and property guidance that follows.

The table below summarizes the key elements in 20MnCr5 and their practical roles for quick technical reference.

| Element | Typical Range (%) | Role/Effect in Alloy |

|---|---|---|

| Carbon (C) | 0.17–0.23 | Determines potential case hardness after carburizing; low core carbon preserves toughness. |

| Manganese (Mn) | 0.70–1.00 | Improves hardenability and strength, supporting uniform case formation and core toughness. |

| Chromium (Cr) | 0.15–0.30 | Increases case hardenability and wear resistance; refines carbides and aids tempering response. |

| Silicon (Si) | 0.10–0.40 | Acts as a deoxidiser and provides slight matrix strengthening and temper stability. |

| Phosphorus (P) | ≤0.035 | Kept low as an impurity; excess P reduces toughness and must be controlled. |

| Sulfur (S) | ≤0.035 | Restricted impurity; small amounts can aid machinability but excess lowers ductility. |

This composition table links each element to its effect in carburized, heat‑treated components and helps define downstream processing and performance expectations.

Which Alloying Elements Define 20MnCr5 Steel and Their Roles?

The main alloying elements in 20MnCr5 — carbon, manganese and chromium — combine to produce the case‑hardening response needed for gears, shafts and similar parts. Surface carbon gained during carburizing controls achievable case hardness after quenching. Manganese enhances hardenability and helps retain core toughness, important for rotating and impact‑loaded components. Chromium deepens hardening and improves wear resistance in the case while stabilising carbide behavior during tempering. Together these elements let designers achieve a hard, wear‑resistant surface with a ductile core — the basis for the specification ranges used in procurement.

What is the Typical Chemical Composition Range of 20MnCr5?

Standards and mill specification sheets set narrow composition ranges for 20MnCr5 to guarantee consistent heat‑treatment response and predictable case/core characteristics. Carbon is kept deliberately low to preserve core toughness while manganese and chromium levels are controlled to balance hardenability and wear performance. Mill tolerances vary by standard and practice, so purchase specifications should cite the ranges above and note acceptable deviations. Confirming composition at order entry reduces the risk of unexpected case depth or hardness during carburizing and avoids costly rework or premature failures in service.

What are the Mechanical Properties and Performance Benefits of 20MnCr5 Steel?

20MnCr5 combines a hard, carburized surface with a tough core, delivering strong wear resistance and solid fatigue performance for contact‑loaded parts. Typical mechanical indicators include moderate tensile strength in the supply condition, a case capable of reaching high HRC after correct heat treatment, and core elongation and impact values that support dynamic loading. The table below gives practical property ranges for specification and design checks. These values help material selection for gears, shafts and pinions where a balanced case/core profile is essential.

Key practical benefits engineers look for when choosing 20MnCr5 for critical components are summarised below.

| Property | Typical Value/Range | Measurement Method / Notes |

|---|---|---|

| Tensile Strength (Rm) | 600–850 MPa (after heat treatment varies) | Measured by standard tensile test; depends on case depth and tempering. |

| Yield Strength (Re) | 350–600 MPa (core-dependent) | Determined on core material after tempering; varies with process. |

| Case Hardness | 58–62 HRC (surface) | Rockwell C on quenched and tempered carburized case; targets vary by application. |

| Core Hardness | 28–40 HRC | Measured beneath the carburized case; indicates retained toughness. |

| Elongation (A) | 10–18% | Percent elongation from tensile test; higher values indicate core ductility. |

These mechanical markers help designers estimate fatigue life and set case depth and hardness targets, which feed into application‑specific guidance and machining planning.

How Do Tensile Strength, Hardness, and Toughness Characterize 20MnCr5?

In 20MnCr5, tensile strength, hardness and toughness are intentionally split between the carburized case and the core — the principle behind the grade’s usefulness. The hardened case provides wear resistance and contact fatigue strength, while the low‑carbon core preserves ductility and impact resistance to prevent brittle failures. Achievable case hardness depends on carburizing and quench parameters; core tensile and elongation values reflect residual load capacity. This case/core contrast lets components resist surface wear while still absorbing shocks — a trade‑off that guides heat‑treatment and design choices for reliable service life.

What Advantages Does 20MnCr5 Offer in Wear Resistance and Machinability?

20MnCr5 strikes a practical balance: in the supply (bright) condition it machines well to tight tolerances; after carburizing and quench/temper, the surface attains high wear resistance. Bright bars give superior surface finish and dimensional accuracy for precision machining before carburizing. The carburized case greatly extends wear life for gears, splines and mating surfaces while the tough core resists crack initiation. Recommended machining practice includes conservative cutting allowances to account for carburizing distortion and selecting tooling grades that handle the alloy’s manganese and chromium content — items to discuss with your supplier and heat‑treater during process planning.

Which Industries and Applications Utilize 20MnCr5 Steel?

20MnCr5 is widely used where a durable surface and resilient core are required: chiefly automotive drivetrains, industrial gearboxes, heavy machinery and agricultural equipment. Its case/core balance makes it ideal for gears, pinions, shafts and transmission parts that face cyclic contact stresses. The list below highlights typical industries and components to help with material selection and procurement requirements. Many suppliers offer 20MnCr5 bright bars suited to these applications, supporting direct sourcing without compromising technical criteria.

- Automotive drivetrains and transmission components are common uses for 20MnCr5.

- Industrial gearboxes and rotating shafts in manufacturing equipment rely on the grade for contact‑loaded parts.

- Agricultural and construction machinery use 20MnCr5 for heavy‑duty linkages and drivetrain components.

These sectors gain from the grade’s wear resistance and fatigue strength; the next section focuses on automotive specifics and supply considerations.

How is 20MnCr5 Steel Used in Automotive Components?

Automotive designers commonly specify 20MnCr5 for gears, pinions, shafts and other transmission parts because carburized surfaces resist pitting and scuffing while the core handles overloads. Typical designs target defined case depths and hardness gradients to meet contact fatigue life and NVH (noise‑vibration‑harshness) requirements in gearboxes. Machining bright bars to precise geometry before carburizing reduces finishing work. For procurement, many mills and distributors list 20MnCr5 among available alloys and can supply bright bars with the dimensional accuracy and surface finish needed for high‑precision automotive manufacturing, simplifying the supply chain for critical parts.

What are the Heavy Machinery and Agricultural Applications of 20MnCr5?

Heavy engineering uses 20MnCr5 for shafts, couplings, pinions and wear‑critical parts that face repetitive contact and shock. The carburized case lowers abrasion and surface fatigue, extending service intervals and reducing replacements in harsh conditions. In agriculture, drivetrain parts and heavy linkages benefit from the core toughness that tolerates impact and torsional loads in the field. These examples show how selecting a case‑hardening grade like 20MnCr5 can cut downtime and maintenance costs, and why appropriate heat‑treatment and inspection criteria are essential in procurement specs.

How is Heat Treatment Applied to Optimize 20MnCr5 Steel Performance?

Optimising 20MnCr5 typically follows a three‑stage heat‑treatment sequence: carburizing to raise surface carbon, quenching to convert the enriched surface to martensite, and tempering to set the required toughness in the core. Each stage has target temperatures and atmosphere controls that determine case depth, hardness gradient and distortion. Good process control creates the desired carbon gradient with a hard case and tempered core, minimises distortion for tight tolerances, and produces fatigue‑resistant microstructures. The steps below outline practical parameters and best practices so engineers and heat‑treaters can align processing with component requirements.

- Stage 1: Carburize parts to the specified case depth with a controlled atmosphere and accurate temperature control.

- Stage 2: Quench in the chosen medium to form a hardened case while limiting unwanted core hardening.

- Stage 3: Temper to relieve residual stresses and balance case hardness with core toughness.

Adhering to these stages limits distortion and produces the microstructural profile required for service; the following sections give more specific carburizing guidance and typical targets.

What is the Carburizing and Case Hardening Process for 20MnCr5?

Carburizing 20MnCr5 exposes the surface to a carbon‑rich atmosphere at elevated temperatures — typically around 900–950°C — for a time set by the required case depth. Carbon diffuses into the surface, creating a gradient that, after quenching, forms a hard martensitic case while the core remains lower in carbon. Typical case depths for gears and shafts range from 0.5 to 2.0 mm depending on the design. Controlling atmosphere composition and part cleanliness is critical to uniformity. After carburizing, parts are prepared promptly for quenching to avoid decarburization; handling bright bars carefully helps preserve surface finish and tolerances.

What are the Quenching and Tempering Guidelines for 20MnCr5 Steel?

Choice of quench medium and tempering regime affects distortion, case hardness and core toughness. For 20MnCr5, common practice is to quench from austenitising temperature in oil or polymer quenchants to manage cooling rate and reduce cracking risk. The quench must be fast enough to harden the case while controlled so the core does not over‑harden and lose toughness. Tempering typically follows at about 150–200°C when higher case hardness is required, or up to 200–300°C when slightly more core toughness is desired — the exact temper depends on service needs. Post‑temper inspections should verify case hardness, case depth and residual stress levels to inform any final straightening or finishing steps.

How Does 20MnCr5 Steel Compare to Similar Grades Like 16MnCr5?

20MnCr5 and 16MnCr5 are both case‑hardening steels used in similar applications, but differences in nominal carbon and manganese affect hardenability and final mechanical properties. A side‑by‑side comparison helps procurement and design engineers select the right grade for load, wear and heat‑treatment plans. The table below summarises key compositional and application differences to support clear decisions when choosing between the two grades or mapping to international equivalents.

| Grade | Carbon (%) | Mn (%) | Cr (%) | Typical Uses | Key Difference |

|---|---|---|---|---|---|

| 20MnCr5 | 0.17–0.23 | 0.70–1.00 | 0.15–0.30 | Gears, shafts, pinions requiring deeper case and higher case hardness | Slightly higher carbon and manganese allowance enabling marginally higher achievable case hardness after carburizing. |

| 16MnCr5 | 0.12–0.19 | 0.50–0.80 | 0.15–0.30 | Similar applications with emphasis on core toughness and lighter wear loads | Lower carbon and manganese base leading to improved core ductility but slightly lower maximum case hardness potential. |

| Equivalent Grades | Varies by standard | — | — | Cross-referenced to EN/DIN equivalents | Selection depends on desired case depth and hardenability differences for specific designs. |

This comparison shows when 20MnCr5 is preferable — typically where a marginally higher case hardness is needed — and when 16MnCr5 may be chosen to prioritise core ductility. The next section maps common standards and equivalents used in procurement.

What are the Key Differences Between 20MnCr5 and 16MnCr5 Steel?

The principal difference between 20MnCr5 and 16MnCr5 is nominal carbon and manganese content and the resulting effect on case hardness and core ductility. 20MnCr5’s modestly higher carbon and manganese allow for a slightly harder case after carburizing, making it suitable for higher‑wear components. 16MnCr5’s lower base values favour marginally better core toughness. Chromium ranges are similar. Engineers choose between them based on required case depth, contact stress levels and allowable core strength; cost and availability can also influence the final selection but technical requirements should dominate the decision.

What International Standards and Equivalents Apply to 20MnCr5?

Procurement should reference international standards to ensure material conformity and interchangeability. 20MnCr5 is commonly cross‑referenced with DIN and EN designations; quoting the relevant standard (for example, EN ISO 683‑3 where applicable) in purchase orders clarifies required composition and heat‑treatment guidance. Specifying standards in tenders and incoming inspection helps align supplier testing and certification with buyer expectations and ensures consistent mechanical performance across batches. Clear standard references reduce ambiguity and support quality assurance throughout the supply chain.

Why Choose Dhand Steels as Your 20MnCr5 Steel Supplier?

Dhand Steels, based in Ludhiana, Punjab, manufactures, supplies and exports bright bars including alloy grades such as 20MnCr5. We focus on dimensional accuracy, reliable mechanical properties and surface finishes suited to precision machining. Our capabilities include improved machinability options, flexible supply formats and quality checks designed to help manufacturers source 20MnCr5 bright bars that meet tight tolerances and finishing needs. Engineers specifying 20MnCr5 for critical parts benefit from suppliers who can deliver bright bars with predictable surface condition and dimensional control ahead of carburizing.

Below are supplier attributes engineers should confirm during procurement to ensure material quality aligns with design requirements.

- High dimensional accuracy to minimise machining allowances and maintain consistent geometry through heat treatment.

- Documented mechanical properties to support predictable fatigue and wear behaviour after specified heat treatment.

- Rigorous inspection and emphasis on surface finish to reduce the risk of decarburization and surface defects during processing.

What Quality Assurance and Certifications Does Dhand Steels Provide?

Dhand Steels prioritises quality checks and client satisfaction across manufacturing and supply processes, focusing on dimensional accuracy and mechanical consistency for bright bars. While specific certificates should be requested during procurement, our practices include inspection regimes and quality control measures that ensure surface finish and dimensional conformity before dispatch. Buyers should request mill test reports and any available inspection documentation for each lot; verifying these documents helps ensure supplied 20MnCr5 bright bars will behave as expected during carburizing and heat treatment, reducing processing surprises.

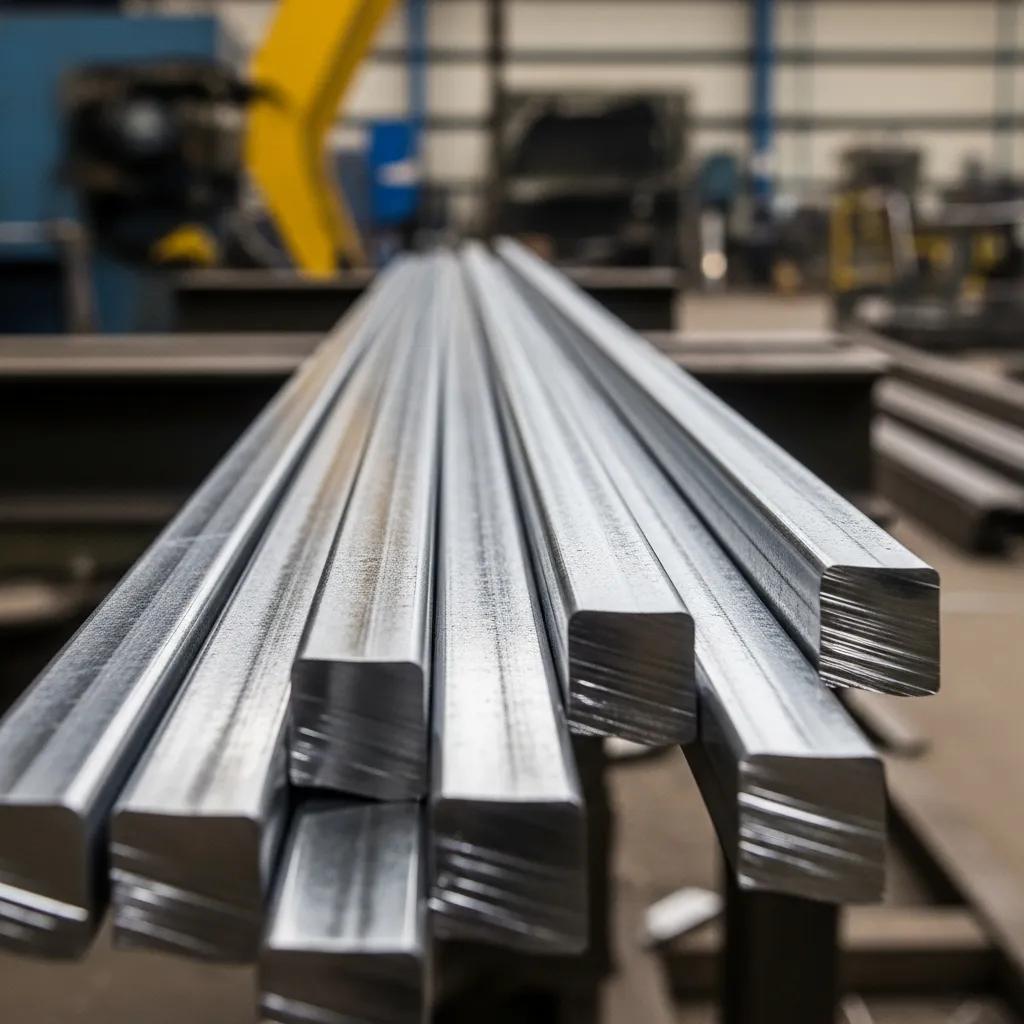

How Does Dhand Steels Customize and Supply 20MnCr5 Bright Bars?

Dhand Steels offers alloy bright bars and special shaped bars, and lists 20MnCr5 among available grades — indicating we can supply round, hex and square bright bar formats for machining and case‑hardening work. Our flexible approach lets us accommodate common shapes and sizes used for gears, shafts and transmission parts while maintaining surface finish and tolerances critical for machining and subsequent heat treatment. For project‑specific needs, request a formal quotation detailing shape, size, tolerance and inspection criteria so supply aligns with part specs and production schedules.

These supplier notes lead naturally to procurement steps such as requesting material certificates and specifying finish and tolerances when ordering 20MnCr5 bright bars.

Frequently Asked Questions

What are the common heat treatment processes for 20MnCr5 steel?

The standard heat treatment sequence for 20MnCr5 is carburizing, quenching and tempering. Carburizing increases surface carbon at elevated temperature to enable a hard case. Quenching transforms the enriched surface to martensite, and tempering at a controlled temperature relieves stresses and restores core toughness. Each stage is essential to reach the intended balance of hardness and ductility for service.

How does the machinability of 20MnCr5 compare to other alloy steels?

20MnCr5 machines well in its bright bar condition, offering a fine surface finish and dimensional accuracy that simplifies pre‑carburizing work. Manganese aids strength but does not unduly harm machinability; however, the hardened case after heat treatment is challenging to machine. Appropriate tooling, cutting parameters and allowances are important, especially for complex geometries.

What are the environmental considerations when using 20MnCr5 steel?

Environmental considerations include managing machining and heat‑treatment waste, proper handling and disposal of lubricants and coolants, and the energy use of heat‑treatment furnaces. Recycling scrap material and adopting eco‑friendlier lubricants and process controls can reduce environmental impact while maintaining production efficiency.

What are the typical applications of 20MnCr5 in the automotive industry?

In automotive applications, 20MnCr5 is commonly used for gears, pinions, shafts and transmission components. The carburized surface resists pitting and scuffing while the resilient core handles shock loads, supporting longevity and reliability in drivetrains and related systems.

How does 20MnCr5 perform under cyclic loading conditions?

20MnCr5 performs well under cyclic loading because a hard, wear‑resistant case withstands repeated contact stresses while a ductile core absorbs shocks and delays crack propagation. This combination makes it a good choice for heavy machinery and automotive parts exposed to continuous loading cycles.

What factors should be considered when sourcing 20MnCr5 steel?

When sourcing 20MnCr5, check the supplier’s quality assurance practices, dimensional tolerances and documented mechanical properties. Ensure the material meets the referenced international standard and obtain mill test reports. Also confirm the supplier’s ability to provide required shapes, sizes and surface finish so the material fits your production schedule and specifications.

Conclusion

20MnCr5 offers a reliable mix of a hard, wear‑resistant surface and a tough core, making it suitable for demanding industrial components. Knowing its composition, mechanical behaviour and heat‑treatment options lets engineers make confident material and process choices. Partnering with a supplier like Dhand Steels — who can deliver bright bars with controlled dimensions and surface finish — helps ensure repeatable results through machining and carburizing. Contact us to discuss your 20MnCr5 requirements and find the right product and tolerances for your application.

Comments

0 Comment On Post