Understanding SAE, EN & IS Steel Standards — A Practical Guide to Grades and Specifications

Steel standards define how metals are named, tested, and supplied. Knowing the differences between SAE, EN and IS reduces procurement risk, ensures the part performs as intended, and helps you write clearer specifications. This guide breaks down the logic behind each system, shows how designations convey chemical and mechanical traits, and offers practical cross-references to help engineers and buyers match materials to applications. You’ll get straightforward criteria for selecting equivalent grades across regions, examples of typical uses, and a clear view of how heat treatment and mechanical properties tie into specification language. We cover SAE numbering and representative grades, how EN codes signal use and delivery conditions, the role of BIS for IS grades, a side‑by‑side equivalency lookup, and a decision checklist for choosing the right standard for your project. Throughout, we connect composition, properties, and processing so you can specify bright bars, alloy steels, and machined components with confidence.

What Are SAE Steel Grades and How Are They Classified?

The SAE system groups steels using a numeric code that reflects composition and primary alloying elements. A four‑digit SAE/AISI code lets engineers quickly infer likely properties and how a steel will respond to processing. Series prefixes — for example, for plain carbon steels and for chromium‑molybdenum alloys — point to dominant elements and expected heat‑treatment behavior. That makes it easier for design and procurement teams to estimate machinability, hardenability and common applications like shafts, fasteners or structural parts. Below is a quick decode of common SAE series with representative grades and their usual uses to help in early material selection.

Use the SAE series table to translate numbering logic into procurement decisions and expected performance.

| SAE Series | Typical Dominant Elements | Common Uses / Example Grades |

|---|---|---|

| 1xxx | Carbon (plain carbon) | General parts and machining — SAE 1018 |

| 4xxx | Chromium‑Molybdenum alloying | Shafts, gears, quenched & tempered components — SAE 4140 |

| 8xxx / 9xxx | Alloyed / Tool steels | High‑strength components and tooling — representative tool/alloy grades |

How Does the SAE/AISI Steel Designation System Work?

SAE/AISI designations pack composition clues into a compact numeric code. The first digit identifies the major series (for example, = plain carbon, = Cr‑Mo alloys), the next two digits refine the composition or subcategory, and the final digit may signal a processing variant or specific formulation. That makes it straightforward to pick a base grade when strength, machinability or hardenability is the priority. For example, SAE 1018 is a low‑carbon steel suited to forming and machining, while SAE 4140 is a medium‑alloy steel commonly used for quenched‑and‑tempered shafts. Learning this digit‑to‑attribute mapping shortens specification cycles and reduces back‑and‑forth with suppliers when you need equivalent EN or IS descriptors.

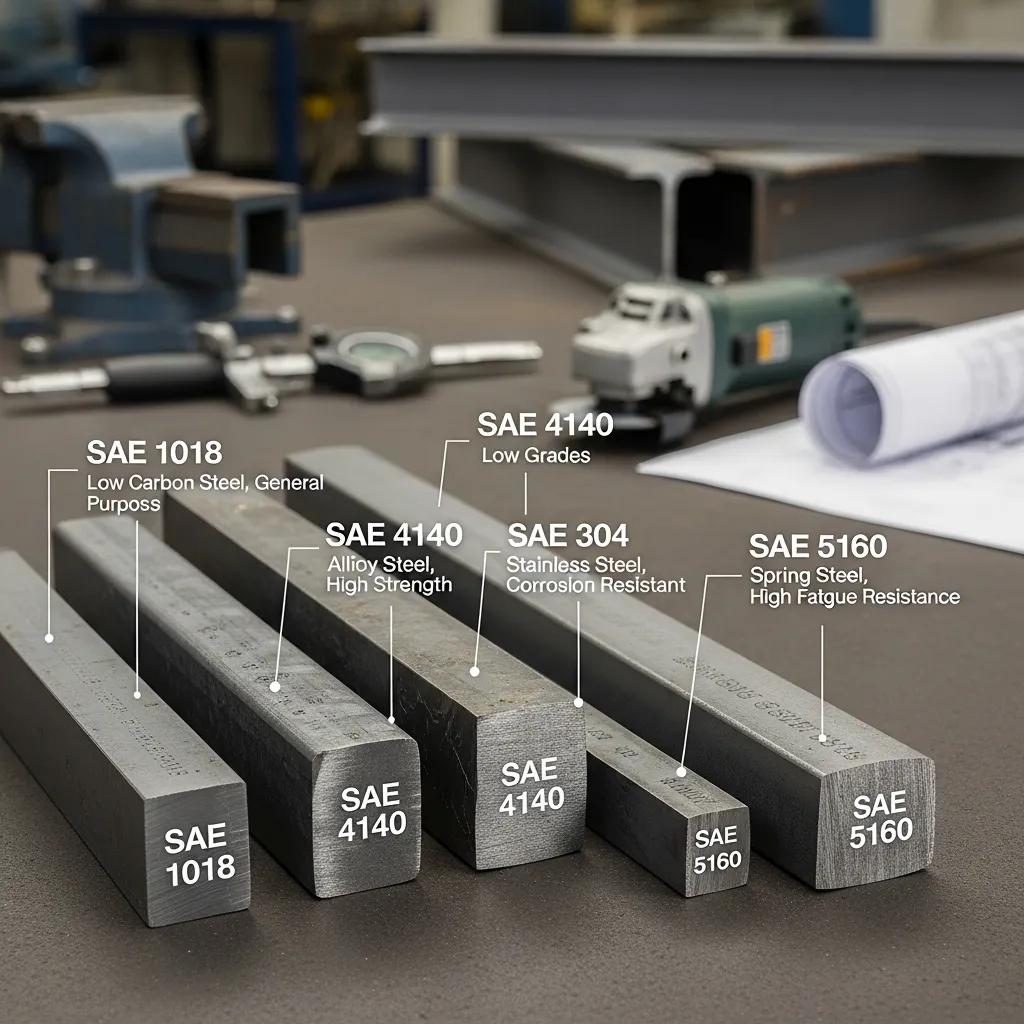

What Are Common SAE Steel Grades and Their Applications?

Several SAE grades are staples across manufacturing, automotive and heavy engineering because their behavior after heat treatment and machining is predictable. Below are representative SAE grades and where they’re typically used, so you can match material choice to part function and processing.

- SAE 1018: Good for machining and forming; weldable with a fine surface finish.

- SAE 4140: Used for shafts, gears and pressure parts where quenched & tempered toughness is needed.

- SAE 1045 / 1050: Medium‑carbon steels for axles and shafts — a balance of strength and ductility.

These mappings make it easier to compare SAE grades with EN or IS equivalents when sourcing internationally.

What Defines EN Steel Standards and Their European Norms?

EN (European Norm) standards, developed within the CEN framework, use alphanumeric codes that communicate intended use, minimum properties and delivery conditions. EN labels typically start with a letter for the application class (for example, “” for structural steels), followed by a number that often reflects minimum yield strength, and may include suffixes indicating delivery or impact test criteria (for example, ). EN focuses on guaranteed properties and supplier delivery conditions rather than exact chemistry, so interpreting EN codes is essential when drafting procurement documents for European projects. The list below decodes common prefixes and suffixes to help you translate an EN designation into expected mechanical behavior and supply state.

- S‑prefix (e.g., S235JR): Structural steels — number commonly denotes minimum yield strength in MPa.

- C‑prefix (e.g., C45): Carbon steels for engineering applications — number indicates nominal strength or carbon band.

- Suffixes (e.g., JR, J0): Indicators for impact test temperature or delivery condition.

Reading EN codes correctly ensures the right delivery conditions and mechanical guarantees are written into contracts for European work, and it helps map those requirements to SAE or IS alternatives.

How Are EN Steel Grades Designated and Categorized?

EN designations combine letters and numbers to show service class and minimum property thresholds, with extra markers for delivery state and test criteria. Decoding a label — for example, (structural steel, ~235 MPa yield, JR = impact test at 20 °C) — reveals whether the steel is meant for structural, engineering or special purposes. EN emphasizes guaranteed mechanical parameters (yield, tensile) and standardized testing, shifting procurement focus to performance outcomes over exact chemistry. That influences how designers specify acceptance tests and surface/finish needs for bright bars and machined parts, and clarifies how EN standards integrate with local manufacturing practices.

Which EN Steel Standards Are Most Used in Industry?

Certain EN grades recur across construction, automotive and engineering sectors because they harmonize mechanical expectations and delivery states, simplifying cross‑border procurement. Common EN references include S235 for general structural use, EN8D for turned engineering components, and EN19/EN24 for higher‑strength alloy steels suited to forging and heat treatment. C45 is a typical carbon grade for shafts and studs. The entries below highlight frequently specified EN grades and their typical applications.

- S235: Structural steel for building frames and welded assemblies.

- EN8D: Engineering steel for machined components and general shafts.

- EN19 / EN24: Quenched & tempered alloy steels for gears, crankshafts and forged parts.

Familiarity with these EN grades simplifies cross‑checking with SAE or IS options when sourcing globally.

How Do IS Steel Specifications Serve the Indian Market?

IS (Indian Standards) specifications are produced by the Bureau of Indian Standards (BIS) to reflect local manufacturing practices, regulations and material availability. IS standards such as IS 2062 (structural steel) and IS 1786 (high‑strength deformed bars) are commonly referenced for public works and industrial projects in India. While IS often parallels international norms, it includes region‑specific delivery conditions, testing protocols and grade names that match domestic supply chains. Knowing IS standards is important for global buyers sourcing from India and for Indian manufacturers specifying materials for local projects — and it makes mapping to SAE and EN counterparts more practical.

Understanding BIS’s role helps procurement teams set appropriate quality assurance and certification expectations when sourcing domestically.

What Is the Role of Bureau of Indian Standards in Steel Grading?

The Bureau of Indian Standards develops and updates IS specifications to secure material quality, safety and interoperability across Indian industries. BIS guidance covers acceptable chemical ranges, mechanical tests and delivery requirements, and it provides conformity assessment and marking systems that aid traceability. For buyers, referencing IS standards in contracts clarifies acceptance criteria and reduces ambiguity at inspection. Knowing BIS responsibilities lets organizations specify required tests, certificates of analysis and mechanical guarantees when sourcing local steel.

Which IS Steel Grades Are Commonly Used in India?

Several IS grades are standard in Indian construction and manufacturing because they balance performance, weldability and cost. IS 2062 is widely used for structural fabrication, while IS 1786 covers high‑strength reinforcement bars. Common carbon grades equivalent to C20/C45 are used for turned parts and shafts. The short list below helps procurement teams choose appropriate domestic grades quickly.

- IS 2062: Structural steel for fabrication, welded sections and bright bars — good strength and weldability.

- IS 1786: High‑strength deformed bars for reinforced concrete.

- Common carbon grades (C20 / C45 equivalents): Typical for turned components and shafts in manufacturing.

Aligning specs with these IS norms reduces custom alloys and conversion work when buying within India.

How Do SAE, EN, and IS Steel Standards Compare?

To compare SAE, EN and IS, map how each system expresses requirements: SAE leans composition‑first, EN emphasizes guaranteed properties and delivery states, and IS reflects domestic conformance for the Indian market. That affects wording in specifications — an SAE‑based purchase expects a particular alloy chemistry, while an EN spec expects minimum yield/tensile figures at a defined delivery condition. The table below offers representative cross‑references showing likely equivalents, composition ranges and typical uses to serve as a practical lookup.

Use this cross‑reference to find likely equivalents and to evaluate trade‑offs when substituting grades across systems.

| Steel Grade (Representative) | Standard System / Designation | Composition Range / Key Property / Typical Application |

|---|---|---|

| SAE 1018 | SAE (1xxx) | Low carbon ~0.15–0.20% C; good machinability; general shafts and bright bars |

| EN8D / C45 | EN / European designation | Medium carbon ~0.42–0.50% C; used for turned shafts and engineering components |

| IS 2062 | IS (BIS) | Structural grade with guaranteed yield ~250–410 MPa depending on class; used for welded structures |

| SAE 4140 | SAE (4xxx) | Alloy steel with Cr‑Mo; higher hardenability and tensile strength for shafts and forgings |

| EN19 / EN24 | EN (engineering alloys) | Quenched & tempered alloy steels for high‑strength forged components |

What Are the Key Differences in Chemical Composition and Mechanical Properties?

Differences in composition — mainly carbon and alloying elements such as chromium, molybdenum and manganese — drive mechanical behavior: tensile and yield strength, toughness and hardenability. A low‑carbon steel like SAE 1018 gives ductility and easy machining but limited hardenability; by contrast, SAE 4140 or EN24 have alloy additions that raise tensile strength and allow quenching and tempering for better fatigue resistance. Thinking in cause‑and‑effect terms (carbon content → strength; alloying → hardenability/wear resistance) helps you specify both chemical limits and required mechanical outcomes in procurement documents, and it informs heat treatment and machining choices downstream.

How Do Regional Preferences and Applications Influence Steel Grade Selection?

Regional norms, supply‑chain logistics and regulatory drivers change which grades are practical in a market. EN grades dominate Europe where delivery‑condition guarantees matter; SAE is common in North America where chemistry‑based specs are routine; IS is prevalent in India because of BIS alignment. These preferences influence lead times, required certificates and what substitutions are acceptable. Stock forms (bright bars, rolled bars, forgings) and local availability often determine the practical choice more than nominal equivalence. Balance ideal material properties against procurement realities and specify acceptable substitutes and qualifiers up front to avoid delays.

How to Choose the Right Steel Standard for Your Business Needs?

Choosing a steel standard starts with your functional requirements, then aligns testing, production and supplier capability. Define loads, fatigue cycles and environmental needs first. Decide whether chemistry‑driven (SAE) or property‑driven (EN/IS) selection suits your inspection and certification process. Factor in manufacturing (machining, forming, heat treatment) and logistics such as regional stock and lead times for bright bars or alloy bars. The checklist below gives a practical order of steps to select a standard‑compliant grade that balances performance with procurement realities.

Work through this checklist to capture technical, commercial and regulatory constraints before locking a grade into a purchase order.

- Define functional requirements: loads, fatigue life, wear and environmental exposure.

- Choose selection basis: chemistry‑focused (SAE) or property‑focused (EN/IS) depending on certification needs.

- Assess processing needs: machinability, formability, heat‑treatment and surface finish requirements.

- Confirm supplier availability: stock, delivery conditions and certificate options with vendors.

- Specify acceptance tests: mechanical tests, chemical analysis and delivery‑condition verification.

Following this checklist makes it straightforward to map industries and applications to recommended grades, summarized in the table below.

The table matches industries to core requirements and suggests candidate grades/standards while noting common supply‑form considerations.

| Industry / Application | Key Requirements | Recommended Grades/Standards & Availability Notes |

|---|---|---|

| Automotive shafts | High fatigue resistance, controlled hardness | SAE 4140 / EN19; commonly stocked as alloy bright bars and forgings |

| Structural fabrication | Weldability, reliable yield strength | IS 2062 / S235 (EN); widely available in structural sections and bright bars |

| General machining parts | Machinability, surface finish | SAE 1018 / C20 / EN8D; often supplied as bright bars for turning |

| Corrosion‑resistant components | Corrosion resistance, hygienic finishes | Stainless grades (304, 316); available as bright bars and machining stock |

What Factors Should Influence Your Steel Grade Selection?

Choose a grade by weighing technical performance, manufacturing compatibility, compliance and supply‑chain realities. Technical drivers include tensile/yield strength, toughness and corrosion resistance. Manufacturing drivers cover machinability, weldability and heat‑treatment compatibility. Commercial factors — lead time, stock formats (bright bars, rolled bars), and supplier certification — affect cost and delivery reliability. Use the checklist below to make procurement documents clear and reduce iterative clarifications during bidding.

- Performance: Required mechanical properties and service conditions.

- Processing: Compatibility with heat treatment, welding and machining.

- Compliance: Applicable standards (SAE / EN / IS) and required certificates/tests.

- Logistics: Stock availability, acceptable substitutes and lead times.

Clear specifications that list desired outcomes and acceptable verification methods reduce ambiguity between buyer and supplier and speed procurement.

How Can Dhand Steels Assist in Selecting Standard‑Compliant Bright Bars?

At Dhand Steels, we manufacture, stock and export bright bars, alloy bright bars and special‑shaped bars across multiple standards. Our inventory and experience cover common grades such as SAE 1018 and SAE 4140, EN8D, EN19, EN24, C20, C45, IS 2062 and stainless grades like 304 and 316 — letting you choose between SAE, EN and IS systems with confidence. We offer precision straightening, customizable shapes and quality checks aligned with your delivery and mechanical specifications. For quotes or detailed certificates, request a formal quotation and grade confirmation so we can provide the right test reports and delivery‑condition documentation before dispatch.

This supplier overview helps procurement teams understand grade coverage and the next steps to secure compliant materials.

Frequently Asked Questions

What are the main differences between SAE, EN, and IS steel standards?

SAE, EN and IS differ in emphasis and typical use. SAE focuses on chemical composition and alloying elements — useful where specific chemistry matters. EN prioritizes mechanical properties and delivery conditions, which matters for structural and certified engineering projects. IS standards serve the Indian market and align with BIS rules and local supply chains. Pick the system that best matches your testing, certification and supply expectations.

How do I determine the right steel grade for my project?

Start with the functional requirements: loads, fatigue, wear and environment. Decide whether chemistry or guaranteed properties are more important for acceptance testing. Then factor in manufacturing (machining, forming, heat treatment) and supplier availability. A simple checklist — functional needs, selection basis, processing, supplier checks and acceptance tests — will guide a reliable choice.

What role does heat treatment play in steel properties?

Heat treatment changes hardness, strength and ductility. Low‑carbon steels like SAE 1018 remain relatively ductile and are easy to machine; alloy steels such as SAE 4140 can be quenched and tempered for higher strength and improved fatigue life. Specify heat‑treatment requirements alongside the grade when those properties are critical.

Are there specific applications where one standard is preferred over others?

Yes. SAE grades are common in North American machinery and automotive work where chemistry specs are standard. EN is preferred in Europe for structural projects that require property guarantees and specific delivery conditions. IS is typically used in Indian construction and manufacturing due to BIS alignment. Choose the standard that aligns with regional project requirements and supplier capabilities.

How can I ensure compliance with steel standards in procurement?

Reference the appropriate standard in contracts, list required grades, mechanical properties and testing protocols, and ask suppliers for certificates and test reports. Work with vendors experienced in those standards and include acceptance tests in your purchase order. Periodic audits and incoming inspection help confirm compliance.

What are the implications of using non‑compliant steel grades?

Non‑compliant materials risk failures, rework, legal exposure and brand damage. They can delay projects and increase cost through replacements or repairs. To avoid these outcomes, stick to specified standards and verify material certificates and test results before acceptance.

Conclusion

Knowing how SAE, EN and IS standards express material requirements helps engineers and procurement teams make precise, practical decisions. By tying composition, mechanical properties and processing together, you can write clearer specifications and choose grades that match part performance and supply realities. If you need help selecting standard‑compliant bright bars or confirming equivalents, contact Dhand Steels — we’ll advise on grades, stock forms and the certificates you’ll need to move your project forward with confidence.

Comments

0 Comment On Post