IS 2062 E350 Steel: Practical Guide to Strength, Load Capacity, and Where Businesses Use It

IS 2062 E350 is a hot-rolled structural carbon steel grade under the Indian Standard where “E350” specifies a minimum yield strength of 350 MPa. This guide breaks down the grade’s defining features, mechanical properties, and practical implications so business owners, engineers, and procurement teams can specify material that meets both performance and cost targets. You’ll learn how yield and tensile strength affect load capacity, which fabrication characteristics matter for welding and machining, and common industry uses across construction, rail, and heavy equipment. We also compare E350 with related grades and international equivalents, and offer procurement tips—price drivers, required documentation, and working with manufacturers. Technical detail is kept actionable so you can avoid overdesign and make confident buying decisions for structural and industrial projects.

What IS 2062 E350 Is — and Why It Matters

IS 2062 E350 is a structural steel grade in the BIS framework intended for welded, riveted, or bolted members. The “E350” tag guarantees a minimum yield of 350 MPa together with balanced ductility suitable for fabrication. This grade is widely used because it delivers a useful strength-to-weight ratio while remaining weldable and formable — attributes that reduce fabrication complexity and cost. Engineers specify E350 when they need predictable behaviour under static and some dynamic loads and when project geometry or welding needs favour a low-to-moderate carbon, hot-rolled steel. Below is a quick reference that summarizes the grade’s identity and primary uses.

This quick facts table gives technical and procurement teams a fast reference before diving into mechanical details.

| Grade Identifier | Classification | Typical Uses |

|---|---|---|

| IS 2062 E350 | Structural hot-rolled carbon steel (E350 = min yield 350 MPa) | Girders, frames, shafts, bright bars, plates |

| Fabrication Traits | Weldable, formable | Suited to welding, bending, machining |

| Design Implication | Strength-to-weight balance | Enables efficient structural sections |

Use this summary in drawings and purchase orders to ensure clarity; the next section covers measurable properties you’ll check on mill certificates.

Dhand Steels supplies IS 2062 E350 in bright-bar and other common product forms, offering grade-compliant material for structural and industrial work — a supplier option to consider alongside your technical evaluation.

Defining IS 2062 E350 — What the Standard Requires

IS 2062 sets chemical and mechanical limits for structural steels; the E350 grade specifically requires a minimum yield of 350 MPa plus defined tensile and ductility criteria to ensure reliable performance in welded and fabricated structures. E350 sits among grades for general construction and engineering where moderate-to-high strength and dependable weldability are important. Commercial product forms include bright bars and plates — used when dimensional accuracy, machining, or surface finish matters in addition to structural strength. Knowing the standard helps specifiers match material to design codes and confirm mill test certificates report the right classification and mechanical minima.

Key Advantages of Choosing IS 2062 E350

E350 combines practical benefits that influence design, fabrication, and life-cycle cost. Below are the main advantages and how they convert into real-world gains.

- High strength-to-weight: The 350 MPa yield lets you use smaller cross-sections than lower grades, reducing material weight and transport expense.

- Good weldability: Low-to-moderate carbon content improves fusion welding performance and can reduce preheat or post-weld requirements in many cases.

- Machinability and finish: Bright-bar and plate forms offer surface quality and dimensional control suited to machining and finishing operations.

- Cost-effectiveness: A practical balance of strength, formability, and availability makes E350 a sound choice for many high-volume structural applications.

Together these advantages support efficient fabrication and durable structures; next we detail the mechanical numbers that underpin those benefits.

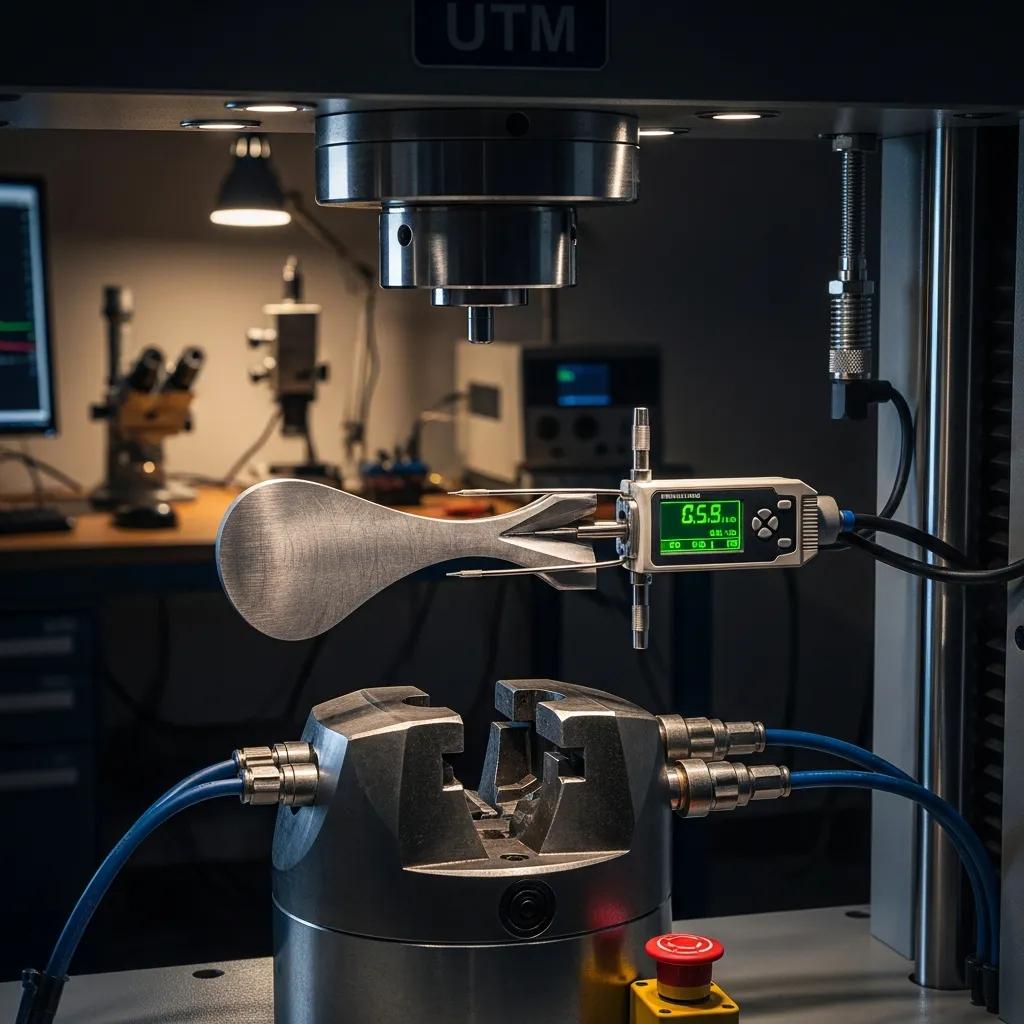

Mechanical Properties of IS 2062 E350

The mechanical properties determine how E350 behaves under load and during fabrication. Designers focus on yield strength, tensile strength, elongation (ductility), hardness (affecting wear and machinability), and impact resistance (toughness). These are measured by standard tests and reported on mill certificates. The table below lists typical ranges engineers use for selection and initial calculations. After the table we translate these figures into practical design and fabrication choices.

This table lists the measurable attributes you’ll verify when designing with E350 or checking supplier test certificates.

| Property | Unit | Typical Value / Range |

|---|---|---|

| Minimum Yield Strength (Rp0.2) | MPa | 350 (minimum specified) |

| Tensile Strength | MPa | 490–630 (typical range) |

| Elongation (A%) | % | 20–26 (typical for adequate ductility) |

| Hardness (HB) | HB | 120–190 (process-dependent) |

| Charpy Impact Energy | J | Variable by subgrade and testing temp |

In practice, yield strength defines allowable stress under service loads while tensile strength shows the ultimate capacity before fracture. Elongation and impact energy indicate ductility and toughness, which affect forming, welding, and behaviour under dynamic or low-temperature service. The next section explains how reputable suppliers demonstrate these properties.

Dhand Steels follows grade-compliant testing and issues mill test certificates with mechanical results per BIS norms, giving procurement teams the traceability and documentation needed to accept material with confidence.

Yield Strength vs. Tensile Strength — What to Use in Design

Yield strength marks the stress where permanent deformation begins; tensile strength is the peak stress before fracture. For E350, a minimum yield of 350 MPa is the primary design parameter for allowable stresses and service-load checks, while the tensile range (about 490–630 MPa) indicates ductile failure margin and informs safety factors. Knowing both values lets engineers compute permissible loads, select section modulus, and choose safety factors for static and cyclic conditions. These metrics also guide decisions to change thickness, alter section geometry, or pick an alternate grade when margins are tight.

Elongation, Hardness, and Impact Resistance — Practical Effects

Elongation controls forming and weld-joint integrity by indicating how much a member can deform without cracking; E350’s elongation typically supports bending and moderate forming. Hardness affects wear resistance and machinability — harder variants improve wear life but can accelerate tool wear. Impact resistance (Charpy) matters for dynamic loading and low-temperature service: higher impact energy reduces brittle-failure risk. Together these properties influence heat treatment, weld preheat, and inspection protocols to secure long-term performance.

How IS 2062 E350 Performs in Load-Bearing Roles

E350 performs reliably in many load-bearing applications because its yield and tensile properties provide a predictable elastic limit and a measurable safety margin. Static structural elements (beams, columns) depend mainly on yield strength and buckling checks; dynamic components (shafts, crane parts) require attention to toughness and fatigue resistance. Connection detailing, welding procedures, and service environment (corrosion, temperature) determine whether E350 is the best choice or if protective measures or an alternative grade are needed. Below we walk through how to convert mechanical specs into design decisions and give examples of typical roles where E350 is commonly used.

Estimating Load Capacity for Structural and Industrial Uses

Converting yield and tensile figures into load capacity requires applying design codes and safety factors, then using section properties (area, moment of inertia) to size members for bending, shear, and axial loads. A simple rule-of-thumb uses yield-based allowable stress × section area for a quick static load estimate, but full engineering checks must include buckling, local yielding, and connection strength per relevant codes. For industrial parts, fatigue life and weld detail are critical, so designers will often require full material traceability and weld procedure qualification. Following these steps helps procurement and engineering teams request the right documents and confirm fabricated parts meet intended load functions.

Why E350 Is Common for Heavy Machinery and Construction

E350 is popular for machinery frames and construction elements because its yield strength combines with fabrication-friendly chemistry to let designers reduce member size without compromising weldability. In machinery, smaller sections can lower inertial mass and improve performance; in construction, predictable behaviour simplifies safety-factor application and inspection. Fabricators appreciate E350’s balance of strength and ductility because it reduces cracking during forming and welding, cutting rework rates. These practical benefits make E350 a frequent choice where durability and manufacturing efficiency both matter.

Typical Applications for IS 2062 E350

IS 2062 E350 is used across sectors where structural performance, weldability, and dimensional accuracy are required. Common applications include building frameworks, bridge components, heavy machinery parts, rail infrastructure, and, where the design allows, certain pressure-containing parts. Each sector emphasizes different properties—bridges focus on fatigue and toughness, machinery emphasizes yield strength and wear performance, and rail demands consistent mechanical properties and surface quality. The list below outlines major sectors and why E350 is often specified.

Major sectors and typical reasons for specifying E350:

- Construction and Buildings: Beams, columns, and connection plates where strength and weldability are essential.

- Bridges and Infrastructure: Strength-to-weight balance suits large spans and fabrication workflows.

- Heavy Machinery and Equipment: Frames, shafts, and assemblies benefit from predictable mechanical properties.

- Rail and Transport Components: Bright-bar forms and consistent properties support durability and machining.

Dhand Steels supplies E350 in product forms such as bright bars and plates, suitable for machined shafts, connector plates, and rail components that require tight dimensional control. These product-form examples illustrate how a supplier catalog can align with sector needs while still requiring technical qualification.

Using E350 in Construction, Bridges, and Infrastructure

In buildings and bridgework, E350 is commonly specified for primary and secondary members — girders, columns, and plates — because its yield strength allows efficient sectioning while weldability and toughness ease fabrication. Designers still need to check fatigue-prone details and confirm weld procedures and protective coatings meet the environment’s durability needs. Fabrication choices such as preheat for large sections, weld filler selection, and post-weld inspection depend on E350’s chemistry and mechanical profile. Mill test certificates and traceable documentation let owners and engineers verify delivered material matches design assumptions and code requirements.

Transport Sector: Automotive, Railways, and Pressure Applications

E350 appears in transport components where moderate-to-high strength and machinability deliver weight savings and service durability — examples include some chassis parts, rail fittings, and fabricated equipment components. Automotive applications value controlled ductile deformation for crash performance; rail parts demand through-thickness toughness and fatigue resistance. For pressure vessels and pressure-containing assemblies, designers must confirm compliance with applicable codes and may require additional testing. Applying E350 in these contexts must always follow the relevant regulatory and design checks.

How E350 Compares to Other Grades

Comparing E350 to lower-strength grades like E250, and mapping it to international equivalents, helps procurement teams balance cost and performance and assess substitution risks. The key quantitative difference versus E250 is the higher minimum yield — allowing lighter sections for the same load — but swaps may change connection details and can carry a price premium. International equivalents (ASTM, EN, JIS) may approximate E350’s mechanical profile, but substitution requires checking chemistry, test methods, and toughness requirements because standards differ in test temperatures and acceptance criteria. The table below offers a side-by-side view to aid specification decisions.

This comparison table maps common grades against E350 for quick decision support when evaluating alternatives or sourcing internationally.

| Grade | Yield Strength | Tensile Strength | Common Uses | Equivalent Standards |

|---|---|---|---|---|

| IS 2062 E350 | 350 MPa (min) | 490–630 MPa | Structural members, bright bars | Comparable to mid-high structural grades (verify chemistry) |

| IS 2062 E250 | 250 MPa (min) | Typically 410–560 MPa | Light structural elements, economy designs | Lower-strength structural grade |

| Selected ASTM/EN grades | Varies (check spec) | Varies | Similar structural applications with different testing | Require mapping and validation |

How E350 and E250 Differ in Practice

The principal difference is numeric: E350’s higher minimum yield reduces required section modulus for a given load, enabling lighter structures. E250 remains useful where lower strength suffices and cost sensitivity is higher. That strength gap affects connection design, weld detail, and allowable stresses — so changing grades is not a simple swap. Cost, availability, and fabrication preferences usually guide the choice; when changing grade, engineers must re-run checks and verify supplier certificates to ensure performance parity.

International Equivalents — What to Check

There’s no automatic one-to-one equivalent for E350 in ASTM, EN, or JIS standards because each defines chemistry limits, test temperatures, and acceptance criteria differently. When working with international suppliers or designs referencing non-Indian standards, compare yield/tensile minima, impact-test temperatures, and chemical composition to confirm functional equivalence. Practical steps include requesting detailed mill certificates, reviewing impact test reports at the specified temperatures, and conducting trial welds or inspections where necessary. These precautions reduce the risk of performance surprises when sourcing abroad.

Sourcing IS 2062 E350: Manufacturers, Pricing, and Availability

Sourcing E350 means evaluating manufacturers for production capability, quality systems, and the product forms you need — bright bars, plates, or custom sections — plus documentation like mill test certificates and dimensional tolerances. Price drivers include raw material markets, section dimensions, added processing (drawing, grinding, machining), quantity, and delivery logistics; lead times depend on production schedules and finishing. Below are procurement steps and a checklist to get accurate quotes and evaluate suppliers without ambiguity.

Checklist for supplier quotes and comparisons:

- Specify Grade and Standard: Clearly state IS 2062 E350 and any required test standards.

- Provide Dimensions and Tolerances: Include section sizes, lengths, and surface-finish expectations.

- Request Documentation: Ask for mill test certificates, heat numbers, and inspection reports for traceability.

These steps help you get apples-to-apples quotes; the following subsections explain how to shortlist manufacturers and understand pricing drivers.

Choosing Manufacturers for IS 2062 E350 in India

Prioritise suppliers that consistently produce bright bars and plates in E350, maintain traceable mill test documentation, and operate QC protocols aligned with BIS. Key selection criteria are production capacity for your product form, in-house testing (mechanical and chemical), and the ability to meet dimensional and surface-finish tolerances. Lead times vary by form and quantity; suppliers offering staged production updates and clear logistics planning typically reduce delivery risk. Use these criteria to shortlist manufacturers who can reliably deliver grade-compliant material.

Price Factors and How to Request Accurate Quotes

E350 pricing is driven by several transparent factors — raw billet cost, section dimensions and weight, any processing (bright-drawing, grinding), finishing tolerances, and market demand. Request detailed line-item quotes to avoid surprises. When asking for quotes include grade (IS 2062 E350), product form (bright bar, plate), dimensions and tolerances, quantity, delivery terms, and required documentation (mill test certificate, inspection). Typical price drivers:

- Raw-material cost: Billet and scrap market prices.

- Processing: Drawing, heat treatment, grinding add per-unit costs.

- Quantity and delivery: Larger orders and inland logistics affect unit price.

If you engage a supplier such as Dhand Steels, request a formal quotation listing product form, quantity, lead time, and certificates; Dhand Steels can quote E350 bright bars and related forms and manage order logistics from their Ludhiana facility. Detailed RFQs yield comparable supplier responses and clearer commercial decisions.

Frequently Asked Questions

1. What sets IS 2062 E350 apart from other structural steel grades?

IS 2062 E350’s defining feature is its minimum yield strength of 350 MPa, higher than lower grades such as E250. That higher yield allows lighter sections for the same load and can improve efficiency. E350’s chemistry also supports good weldability and ductility, making it suitable for more demanding structural and machinery applications. When comparing to international standards, always verify mechanics and test criteria since specifications can differ across standards.

2. How does fabrication differ for IS 2062 E350?

Fabrication is influenced by E350’s weldability and ductility. Its low-to-moderate carbon content typically permits easier welding with less preheat and fewer post-weld treatments versus higher-carbon steels, which is an advantage for complex welded structures. Its machinability and surface finish in bright-bar forms facilitate accurate shaping and tight tolerances.

3. What environmental factors matter when using IS 2062 E350?

Key environmental considerations are recyclability and production energy use. Steel is highly recyclable, which reduces lifecycle impacts, but steelmaking and fabrication consume energy and produce emissions. To limit environmental footprint, source E350 from manufacturers using energy-efficient processes or electric arc furnaces and look for environmental management practices in their operations.

4. What documentation should be requested when buying IS 2062 E350?

Essential procurement documents include mill test certificates (mechanical and chemical results), heat numbers for traceability, and any inspection reports confirming dimensional tolerances. Where required, request impact-test reports, weld procedure qualifications, and third-party inspection certificates to match project specifications.

5. How does E350 behave in extreme weather or harsh environments?

E350 performs well across a range of temperatures, but service conditions matter. Its yield strength and toughness give good resistance to temperature swings and dynamic loads. For harsh environments — coastal, highly corrosive, or very low temperatures — apply appropriate coatings, corrosion protection, or select subgrades/tests that ensure adequate toughness at service temperature.

6. What are the cost implications of using E350?

Costs depend on raw-material prices, processing, and demand. While E350 can be pricier than lower grades up-front, its higher strength often reduces material quantity and transportation costs, and its fabrication-friendly properties can lower labour and rework expenses. A project-specific cost-benefit assessment will show whether E350 delivers net savings.

7. Is E350 suitable for pressure vessels?

E350 can be used in pressure-containing applications only with proper design verification and testing. Pressure vessels require compliance with specific codes and may need additional inspections or material tests. Engineers must confirm that E350’s properties and any required testing meet the applicable pressure-vessel standards before acceptance.

Conclusion

IS 2062 E350 is a practical, well-balanced structural grade — offering a useful strength-to-weight ratio with good weldability and fabrication traits. For business owners and engineers, understanding its mechanical profile and procurement considerations helps specify the right material, avoid overdesign, and manage costs. Use the guidance here to evaluate E350 for your next project, and reach out to suppliers like Dhand Steels for grade-compliant bright bars, plates, and supporting documentation when you’re ready to procure.

Comments

0 Comment On Post