How Steel Grade Selection Affects Cost and Product Life — A Practical Guide for Business Owners

Picking the right steel grade shapes your manufacturing costs, the service life of parts, and overall return on investment. This guide breaks down how grade choice changes raw-material and fabrication expenses, drives maintenance and replacement cycles, and affects sustainability outcomes — all written for business owners responsible for procurement or design decisions. Mechanical and chemical traits (tensile strength, corrosion resistance, machinability, weldability) determine how a part performs under load, in corrosive environments, and through repeated processing steps — and those factors together set lifecycle cost. Read on for a practical framework to compare common grades, quantify cost drivers, and match grade choice to your production capabilities and sustainability targets. We map the main grade families and their properties, weigh material vs fabrication trade-offs, look at long-term maintenance impacts, suggest manufacturing optimizations, review sustainability benefits, and explain how Dhand Steels’ bright bars can support smarter purchasing decisions. Throughout, we use engineering-economics and lifecycle-cost thinking so you can minimize total cost of ownership while maximizing product life.

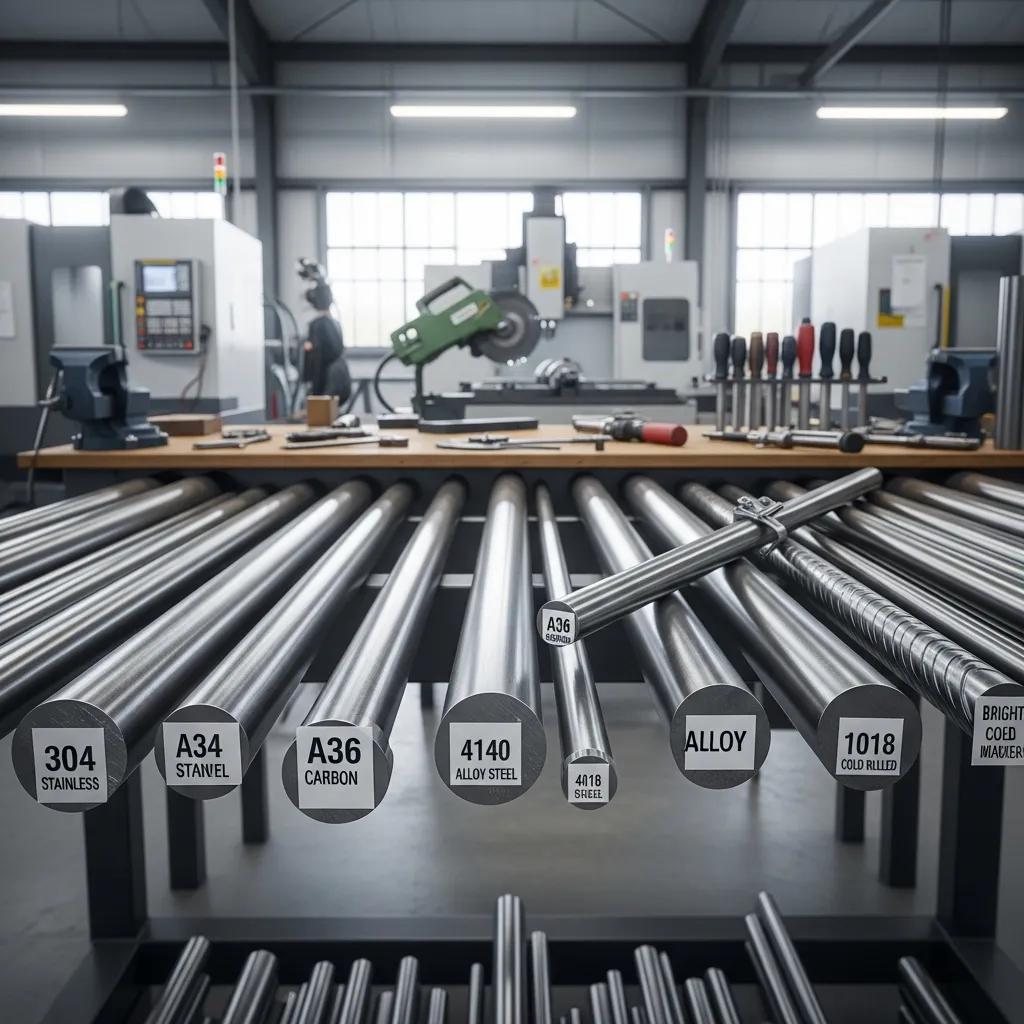

What Are the Key Steel Grades and Their Core Properties?

Steel grades fall into families — carbon steels, alloy steels, stainless steels, and tool steels — with composition and processing that define strength, ductility, corrosion resistance and machinability. Those properties drive cost and product life in predictable ways: higher tensile strength can reduce section size for the same load, better corrosion resistance lowers inspection and coating costs, and good machinability shortens cycle times and reduces tooling wear. When choosing a grade, evaluate application drivers such as cyclic loading, exposure to corrosive agents, and the required surface finish — these criteria predict lifecycle cost more reliably than the purchase price alone. The table below gives a quick comparison of common grades and their primary attributes to help you shortlist candidates for a detailed lifecycle-cost analysis.

This table compares representative grades and attributes to support a fast triage of material candidates.

| Grade | Typical Composition Notes | Tensile Strength (approx) | Corrosion Resistance | Machinability |

|---|---|---|---|---|

| SAE1018 | Low‑carbon steel with controlled carbon content | ~440–550 MPa | Low (requires coating) | High — easy to machine |

| EN8 / EN8D | Medium‑carbon steel; balanced strength and ductility | ~600–800 MPa | Low–moderate | Moderate machinability |

| C20 | Mild carbon steel commonly used in Europe | ~400–600 MPa | Low | Good machinability |

| SAE4140 | Chromium‑molybdenum alloy steel | ~800–1,100 MPa (heat‑treated) | Moderate | Lower machinability when hardened |

| IS2062 E350 | Structural steel designed for welded assemblies | ~450–700 MPa | Moderate (depends on coating) | Good for forming; machining varies |

| Stainless 304 (hyponym) | Austenitic stainless with ≈18% chromium | ~500–700 MPa | High (stable passive film) | Lower machinability than carbon steels |

Which Steel Grades Does Dhand Steels Offer and What Are Their Characteristics?

Dhand Steels stocks a broad range of bright bars and related forms in commonly used grades — SAE1018, EN8D, C20, SAE4140, IS2062 E350 and EN8 — so manufacturers can choose the balance of strength, machinability and cost that fits the application. SAE1018 and C20 work well where machinability and surface finish matter for light‑to‑moderate loads. EN8/EN8D gives a step up in strength for shafts and pins that need higher load capacity. SAE4140 is the go‑to for high‑stress parts that will be heat‑treated for tensile and fatigue strength, though it adds processing complexity and tooling demands. IS2062 E350 is commonly specified for welded structural members where formability and consistent weld behaviour matter. Our bright bars offer tight dimensional accuracy and superior surface finish, which narrows lifecycle‑cost modelling and reduces secondary work. Reviewing in‑stock grades is a practical next step before running fabrication cost scenarios.

How Do Mechanical Properties Like Tensile Strength and Corrosion Resistance Affect Product Life?

Tensile strength, toughness and fatigue resistance determine how a component handles static and cyclic loads. Choosing a grade with the right yield and fatigue properties reduces crack initiation and propagation, extending service intervals. For example, a drive shaft made from EN8D or heat‑treated SAE4140 will withstand higher alternating stresses and deliver more cycles to failure than one made from lower‑strength mild steel — cutting replacement frequency and downtime costs. Corrosion resistance works differently: grades with a protective passive film (stainless 304) or higher alloying resist uniform and pitting corrosion, preserving cross‑section and preventing premature fatigue failures in aggressive environments. Often, combining higher strength with corrosion resistance raises material cost, but in harsh conditions it can lower lifecycle cost. Engineers should calculate the break‑even between the upfront material premium and reduced maintenance to make informed choices. These property comparisons naturally feed into material vs fabrication cost analysis for procurement.

How Does Steel Grade Selection Influence Material and Fabrication Costs?

Grade choice impacts three main cost channels: material price, fabrication complexity (machining, welding, heat treatment), and tooling or consumable wear — together these set the manufacturing cost per part. Material price often dominates the initial budget, but fabrication steps — longer cycle times on hard alloys, heat‑treat requirements, or pre/post‑weld treatments — can make a cheaper grade costlier overall. The table below maps grades to the principal material vs fabrication cost drivers so you can estimate where extra spend will occur and whether it’s justified by lifecycle benefits.

This table outlines relative material and fabrication impacts by grade to support procurement trade‑off decisions.

| Grade | Material Cost (relative) | Machinability Impact | Welding Difficulty | Heat Treatment Need |

|---|---|---|---|---|

| SAE1018 | Low | Low — reduces cycle time | Easy | Rarely required |

| C20 | Low | Low | Easy | Usually none |

| EN8 / EN8D | Medium | Moderate — tools wear faster | Moderate | Sometimes used to tune strength |

| SAE4140 | High | Lower machinability when hardened | More difficult — may need preheat/postheat | Often required for performance |

| IS2062 E350 | Medium | Good for forming; machining varies | Designed for welding | Rare, depending on spec |

What Are the Material Cost Differences Among Common Steel Grades?

Price differences reflect alloy content, production route and market supply. Low‑carbon grades like SAE1018 and C20 are usually the most economical per kilogram, while alloy steels such as SAE4140 carry a premium for added elements and heat treatment. Regional availability and supply chains also shape price bands: structural grades like IS2062 may be competitively priced locally, while specialty alloy rounds can have longer lead times and higher cost. If budget constraints exist, test whether a cheaper grade’s lifecycle penalties — faster wear, higher maintenance or shorter service life — outweigh upfront savings by running a simple lifecycle‑cost estimate over the expected service years. Understanding these price bands helps procurement decide when paying a material premium reduces total cost of ownership, and it guides choices around machining, welding and heat treatment trade‑offs.

How Do Machinability and Weldability Affect Fabrication Expenses?

Machinability and weldability determine labour hours, tooling replacement rates and the need for specialised consumables or secondary treatments. High‑machinability steels shorten cycle times, reduce cutter wear and lower scrap; poor machinability raises running costs. For welding, grades that need preheat, controlled interpass temperatures or special filler metals add process time and QA overhead; easily weldable grades reduce rework and NDT needs. Practical mitigations include specifying near‑net bar sizes to limit machining allowance, using cutters and coatings suited to the alloy, and standardising on a narrow set of grades to shorten setups. These steps support manufacturing cost optimisation through lean practices and grade consolidation.

What Are the Long-Term Maintenance and Replacement Cost Implications of Steel Grade Choices?

Material selection is a primary lever for lifecycle costs because maintenance frequency, inspection needs and replacement cycles depend on corrosion behaviour, fatigue life and wear resistance. Corrosion‑prone grades incur repeated coating, inspection and repair expenses; fatigue‑sensitive materials increase unplanned downtime and earlier replacement, multiplying total cost through lost production. A proper lifecycle‑cost analysis should include expected maintenance intervals, downtime cost per event and failure probabilities under service conditions to compute a present‑value comparison between grades. The sections below quantify how corrosion resistance and fatigue strength translate into maintenance savings and replacement frequency.

How Does Corrosion Resistance Extend Product Lifespan and Reduce Maintenance?

Corrosion resistance slows cross‑section loss and surface degradation, reducing inspection frequency, coating refresh cycles and emergency repair costs in corrosive settings like marine, agricultural or chemical environments. Practically, a more corrosion‑resistant grade can extend inspection intervals from annual to multi‑year cycles and lower maintenance labour and consumable costs significantly depending on exposure severity. In salt‑spray or aggressive chemical environments, stainless variants or sacrificially coated carbon grades often deliver the best total‑cost outcome despite higher upfront material cost. Running a 10‑year scenario that compares coating and downtime costs typically reveals the break‑even point where a premium grade becomes cost‑effective — and that analysis should guide grade selection for long‑lived assets.

What Is the Impact of Fatigue Strength on Structural Integrity and Replacement Frequency?

Fatigue strength controls how many load cycles a component tolerates before crack initiation and is critical for rotating shafts, linkages and cyclically loaded structures. Choosing a higher fatigue‑strength grade or improving surface finish can lengthen service life substantially. In technical terms, selecting a superior fatigue grade shifts the S‑N curve upward, increasing cycles to failure and lowering the chance of premature cracking; practical measures include selecting alloy steels with appropriate heat treatment or increasing section sizes to reduce stress amplitudes. Designers should apply fatigue‑focused safety factors and, where possible, validate choices with sample testing — these steps reduce costly replacements and align part life with maintenance plans.

How Can Manufacturing Cost Optimization Be Achieved Through Strategic Steel Grade Selection?

Strategic grade selection helps optimise manufacturing cost by cutting processing steps, reducing scrap and matching material choice to existing equipment and heat‑treatment capabilities. Choose grades that machine well on your tooling or avoid mandatory quench‑and‑temper cycles to shorten lead times and lower per‑part cost. Adopting standard stock lengths and a small palette of grades enables lean inventory practices that reduce changeovers and scrap. The following sections outline lean principles and energy/waste considerations that, combined with the right grade strategy, deliver manufacturing savings.

What Lean Manufacturing Principles Support Cost Reduction in Steel Fabrication?

Applying lean principles — standardise grades, minimise work‑in‑progress and reduce handling — cuts non‑value‑added cost by reducing changeovers and scrap. Standardising a limited set of grades and bar dimensions lets you secure bulk discounts and reduce tooling setups, while Kanban for common bright‑bar sizes prevents overstock and obsolescence. Choosing grades that avoid extra heat treatment or special welding prep eliminates cycle time and inspection tasks. These lean moves multiply the cost benefits of selecting grades that match production capability and lead naturally into energy‑and‑waste improvements tied to grade choice.

- Standardised work and inventory control reduce waste.

- Kanban for bar lengths cuts overstock and handling costs.

- Grade consolidation lowers tooling changeovers and scrap.

Used together, these tactics make grade selection a leverage point for continuous production cost improvement and open the door to energy‑focused optimisations.

How Do Energy Efficiency and Waste Reduction Relate to Steel Grade Choices?

Energy and waste drivers include heat‑treatment needs, machining allowance (material removed) and scrap from rejects. Grades requiring heavy heat treatment or large machining allowances raise both energy use and material waste. Selecting near‑net shapes or grades that machine cleanly reduces energy per part and cuts scrap volume, and choosing recycled‑content or EAF‑produced steels (when available) lowers the material’s embodied energy. Process changes — for example replacing some heat treatment with cold work or surface coatings — can further reduce energy intensity. Practical steps: specify tolerances that limit machining allowance, standardise heat‑treatment cycles across families, and work with suppliers to source materials with lower embodied energy.

What Are the Sustainability Benefits of Choosing Smarter Steel Grades?

Choosing smarter grades and production routes reduces embodied carbon, lowers regulatory risk and produces operational savings over an asset’s life by cutting energy‑intensive processing. “Green steel” pathways — higher recycled content and electric‑arc‑furnace production — typically reduce embodied carbon compared with blast‑furnace routes. Grades optimised for recyclability and reduced processing needs also shrink lifecycle environmental impact. For business owners, these sustainability benefits can unlock procurement incentives, simplify compliance, and differentiate your offering in sustainability‑conscious markets. The table below summarises production‑method and grade‑level sustainability attributes to guide sourcing decisions.

This table shows relative sustainability attributes for production methods and grades to help with procurement choices.

| Production Method / Grade | Embodied Carbon (qualitative) | Recycled Content | Energy Intensity |

|---|---|---|---|

| EAF-produced recycled steels | Low | High (>70% typical) | Lower than BF routes |

| Conventional BF-BOF steels | High | Low–Moderate | High |

| Grades optimized for formability (less machining) | Moderate | Variable | Lower process energy |

| Stainless (304) | Higher due to alloying | Moderate | High, but long life offsets impact |

How Does Green Steel Production Reduce Carbon Footprint and Operational Costs?

Green steel methods — electric‑arc furnaces with high scrap input or emerging hydrogen reduction processes — lower carbon emissions per tonne and reduce exposure to carbon pricing or regulatory costs. Operational advantages appear when lower embodied carbon unlocks procurement incentives, lowers offsetting needs or eases compliance in sustainability‑sensitive supply chains. That said, green routes have different price and availability profiles, so run lifecycle‑cost and supply‑risk assessments to decide when green steel is both environmentally and economically preferable. Prioritising green‑produced bars where lifecycle analysis shows net benefit supports both cost and compliance goals.

What Role Does Recycled Steel Play in Sustainable Manufacturing?

Recycled steel cuts reliance on primary ore and significantly lowers embodied carbon when sourced from high‑scrap EAF producers. It typically meets mechanical needs for many bright‑bar uses but requires QA to ensure consistency. Procurement best practices include requesting mill certificates for recycled content, verifying mechanical test data, and partnering with suppliers who trace their scrap sourcing. Where surface finish or performance is critical, validate recycled‑content bars with pilot runs to confirm machining behaviour and final part results. These steps balance sustainability gains with the operational certainty needed for repeatable manufacturing.

How Do Dhand Steels’ Bright Bars Provide Cost and Product Life Advantages?

Dhand Steels manufactures, supplies and exports bright bars in round, hex and square profiles, plus HHB/HB wires, across grades such as SAE1018, EN8D, C20, SAE4140 and IS2062 E350. Our offering helps buyers align material choice with lifecycle objectives. Our bright bars are produced with tight dimensional accuracy and a premium surface finish, reducing secondary machining and fitting time on the shop floor and lowering fabrication cost per part. Project snapshots show measurable improvements in machining yield and reduced rework when precision bar stock is used, and our flexible grade range supports material standardisation across production lines. For tailored comparisons or quotes, request a technical consultation so we can map grade selection to expected lifecycle‑cost savings for your application.

What Case Studies Demonstrate Cost Savings and Extended Product Life with Dhand Steels?

Representative project summaries highlight common results: specifying precision EN8D bright bars for rotating components reduced machining allowance and tool wear, cutting per‑part machining time and lowering scrap; in another case, switching critical structural parts to IS2062 E350 bright bars improved weld consistency and reduced on‑site rework. These conservative outcomes focus on reduced fabrication time and extended service intervals rather than sweeping percentage claims, showing how supplier grade choice and dimensional accuracy together lower total cost of ownership. For full case details and project metrics, contact us for in‑depth studies or a technical quote.

How Can Business Owners Customize Steel Solutions for Optimal Performance and Cost Efficiency?

Customization follows a simple consultative path: define service conditions and lifecycle targets, shortlist grades by mechanical and corrosion needs, run prototype and machining trials, then validate performance with small‑batch production before scaling. Dhand Steels supports specification selection by offering multiple bright‑bar grades and advising on near‑net sizing to reduce machining allowance; this collaboration shortens validation cycles and aligns supplier capability with your manufacturing constraints. Start early conversations about fatigue loads, environmental exposure and fabrication processes so the chosen grade minimises lifecycle costs and yields predictable production outcomes.

- Define functional requirements and lifecycle targets before selecting material.

- Shortlist grades that match mechanical and corrosion requirements.

- Validate with prototype runs and iterate on near‑net bar sizing to reduce machining waste.

Following these steps leads to more predictable production costs and longer product life through aligned material and process choices.

Frequently Asked Questions

What factors should I consider when selecting a steel grade for my project?

Consider mechanical properties — tensile strength, ductility and corrosion resistance — because they determine part performance and longevity. Also assess the application: load types, environmental exposure and required surface finish. Factor in cost impacts such as material price and fabrication expenses, plus availability and any sustainability benefits that can affect operational costs and regulatory compliance.

How can I determine the right steel grade for a specific application?

Start by listing the operating conditions: static or dynamic loads, corrosive or high‑temperature environments, and required mechanical properties. Use material property charts to match needs to candidate grades, and consult suppliers or industry experts for recommendations based on similar applications. Prototype testing is valuable to validate the choice before full production.

What are the implications of using recycled steel in manufacturing?

Recycled steel cuts the carbon footprint by requiring less energy than virgin steel and often meets mechanical requirements for bright‑bar applications. Quality assurance is essential: request mill certificates, review mechanical tests and run pilot production when necessary. Sourcing recycled steel can improve sustainability credentials and may unlock procurement incentives, but it must be validated for your specific performance needs.

How does the choice of steel grade affect maintenance schedules?

Grade choice influences maintenance through corrosion resistance, fatigue life and wear characteristics. More corrosion‑resistant grades need fewer inspections and refresh cycles; materials with higher fatigue strength extend service intervals. Selecting the right grade can therefore reduce maintenance costs and downtime over the asset’s life.

What role does heat treatment play in steel grade selection?

Heat treatment changes strength, hardness and toughness and is a key factor in grade selection. Some grades, like SAE4140, typically require heat treatment to hit target properties, which raises fabrication complexity and cost. Low‑carbon steels often need little or no heat treatment. Understanding these requirements helps you evaluate total manufacturing cost and match the grade to production capabilities.

How can I optimize manufacturing costs through steel grade selection?

Choose grades that match your existing machining and fabrication capabilities to minimise processing steps. Prefer materials that reduce heat‑treatment needs and machining allowance, and standardise on a small range of grades to cut tooling changeovers and scrap. Always account for lifecycle costs — maintenance and replacement — not just upfront material price.

What are the sustainability advantages of using green steel production methods?

Green steel methods, such as EAF production with high scrap input, significantly lower carbon emissions versus traditional blast‑furnace routes. These approaches increase recycled content, reduce reliance on virgin materials and lower environmental impact. Adopting green steel can enhance sustainability credentials, support regulatory compliance and, in some cases, reduce operational costs over the asset lifetime.

Conclusion

Choosing the right steel grade is central to lowering manufacturing costs, extending product life and meeting sustainability goals. By understanding mechanical properties and the trade‑offs between material and fabrication costs, business owners can make decisions that align with production targets and total cost of ownership. Dhand Steels supplies a wide range of high‑quality bright bars to help you match grade choice to application needs and lifecycle objectives. Contact us to explore options and find the steel solution that best fits your business.

Comments

0 Comment On Post