Purchasing high-quality steel is the first step toward creating superior engineering components. However, unlocking the full potential of materials like alloy and case hardening steels often requires a critical post-purchase process: heat treatment. As a leader in specialized heat treatment steel India relies on, Dhand Steels understands that how you process our steel is just…

How Dhand Steels Ensures Dimensional Accuracy Across Every Batch

In high-precision industries like automotive and general engineering, consistency is not just a goal; it is a requirement. For quality managers and engineers, the slightest variation in a material's dimensions can lead to production delays, tool damage, and component failure. This is why sourcing steel with guaranteed precision is critical. As a leading provider of…

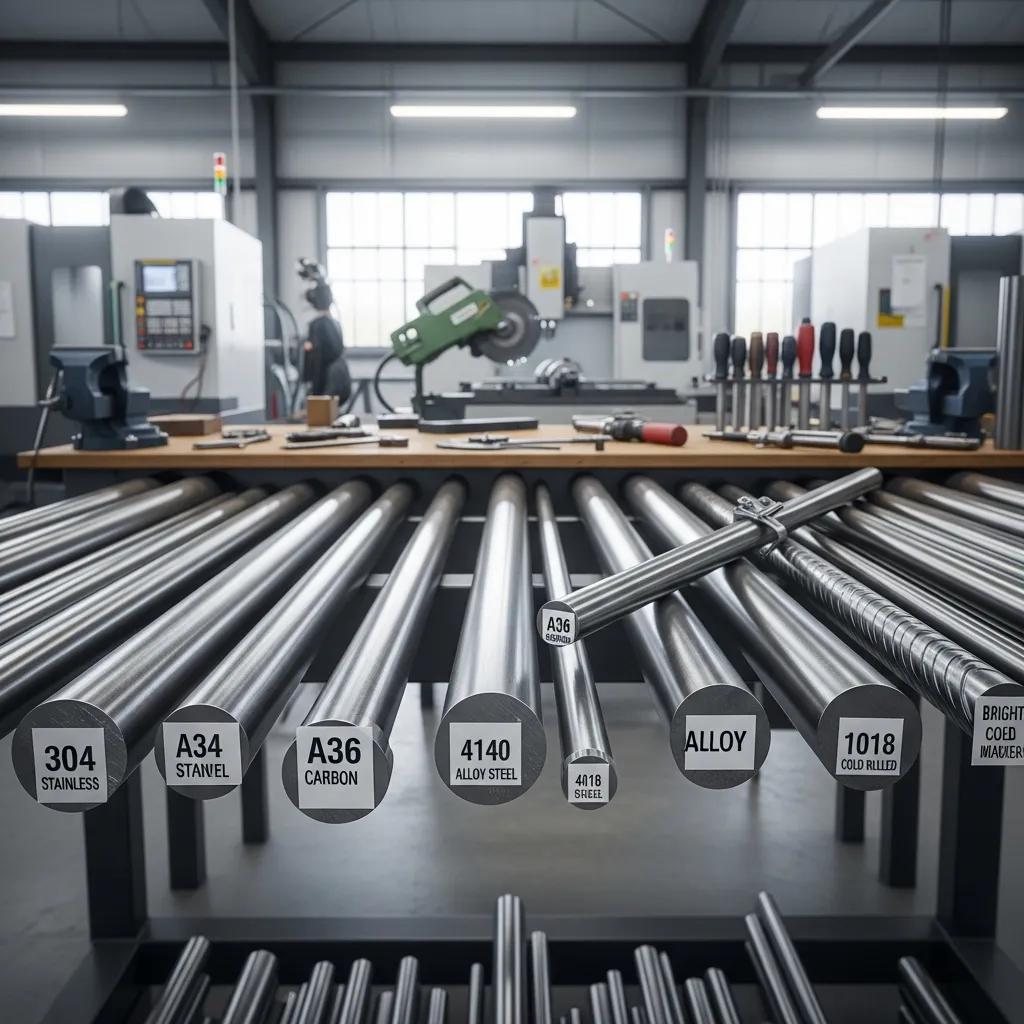

Choosing the Right Steel Grade for Automotive Components: Expert Guide by Dhand Steels

In the highly competitive automotive industry, every component matters. The safety, performance, and fuel efficiency of a vehicle depend heavily on the materials used in its construction. This makes selecting the right steel grade a critical decision for engineers and OEMs. As one of the leading automotive steel suppliers India has, Dhand Steels provides this…

SAE 4140 vs EN19 Steel: Which Alloy Steel Is Better?

SAE 4140 vs EN19: Which Alloy Steel Best Fits Your Application?SAE 4140 and EN19 are common chromium‑molybdenum alloy steels used across automotive, heavy engineering and oil & gas applications. SAE 4140 offers a well‑balanced mix of toughness and ductility, while EN19 can reach higher tensile strength and hardness after heat treatment. This article breaks down…

C45 Steel: Why It’s the Most Widely Used Medium Carbon Steel

C45 Steel — Why It’s the Most Widely Used Medium‑Carbon Steel: Properties, Applications & Supplier InsightsC45 steel is a medium‑carbon engineering steel (nominal C ≈ 0.42–0.50%) prized for a practical balance of strength, machinability and heat‑treatability. This guide explains why C45 (commonly specified alongside equivalents such as AISI 1045 and EN 1.0503) is a go‑to…

SAE 4140 Steel: Properties, Heat Treatment & High-Stress Applications

SAE 4140 Steel — A Practical Guide to Properties, Heat Treatment and High‑Stress ApplicationsSAE 4140 is a chromium–molybdenum low‑alloy steel commonly selected for demanding engineering parts because it blends hardenability, toughness and fatigue resistance in a heat‑treatable package. This guide walks through the alloy chemistry, key mechanical data and the heat‑treatment routes — annealing, normalizing,…

EN18 Steel: Why It’s Preferred for Automotive Components

EN18 Steel: The Practical Choice for Automotive ComponentsEN18 is a medium‑carbon chromium alloy designed to balance strength, toughness and machinability for many automotive parts. This piece explains EN18’s chemistry and performance, and shows how composition and heat treatment deliver the tensile strength, hardness and fatigue resistance needed for rotating and load‑bearing components. Engineers and procurement…

How Steel Grade Selection Impacts Cost & Product Life

How Steel Grade Selection Affects Cost and Product Life — A Practical Guide for Business OwnersPicking the right steel grade shapes your manufacturing costs, the service life of parts, and overall return on investment. This guide breaks down how grade choice changes raw-material and fabrication expenses, drives maintenance and replacement cycles, and affects sustainability outcomes…

Discover SAE 1018 Steel Properties & Applications

SAE 1018 Steel: Practical Guide to Properties, Composition and Industrial ApplicationsSAE 1018 is a low‑carbon, cold‑finished engineering steel commonly supplied as machinable bright bars. It strikes a dependable balance between ductility, formability and workable strength—making it a frequent choice for shafts, pins, fasteners and other general‑purpose components. This guide breaks down what 1018 is, the…

Unveiling EN19 Steel Applications: A Guide for Engineers

EN19 Steel — High‑Tensile Cr–Mo Alloy: Properties, Uses and Industrial ApplicationsEN19 is a high‑tensile chromium–molybdenum alloy steel engineered for demanding engineering parts that need a careful balance of strength, toughness and wear resistance. This guide breaks down EN19’s chemistry, mechanical performance, heat‑treatment routes, common international equivalents and the industrial uses that make it a preferred…

© Copyright 2026 All Rights Reserved. | Privacy Policy | Terms & Conditions